The Right Transfer Pump for the Job

No leaks. No guesswork. From totes to day tanks, Liberty specs transfer pumps that run dry, handle solids, and stop vapor-lock — protecting uptime and budgets.

Run-Dry Safe, Self-Priming, Solids-Friendly

Wins on dirty/viscous/abrasive streams, tote transfers, intermittent duty, and anywhere air is available.

- Self-priming to ~15–20 ft dry lift.

- Run-dry & dead-head tolerant (no seal burn-out).

- Solids to ¼–2″ depending on model.

See examples & ROI›

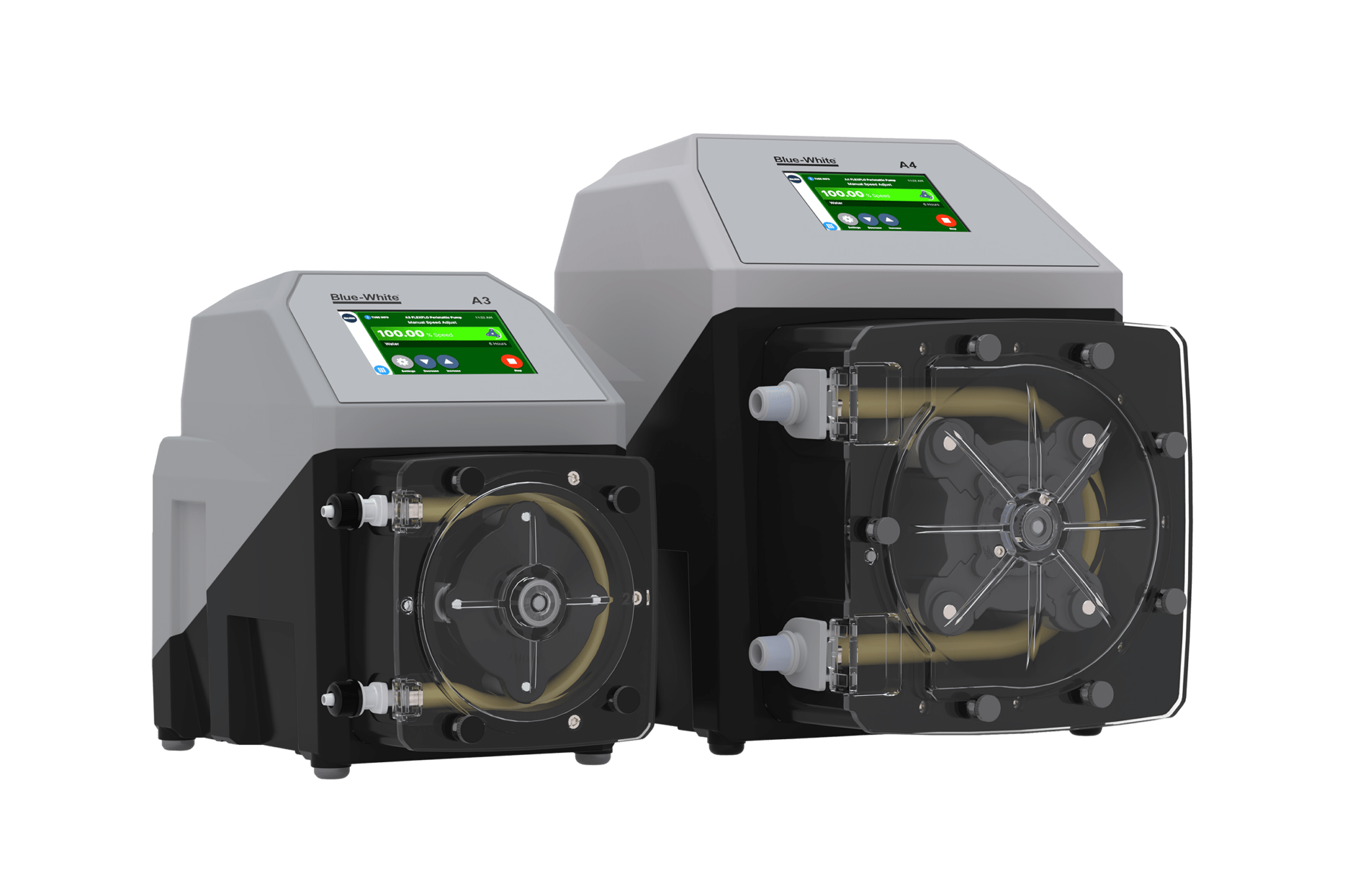

Vapor-Lock Proof, Reversible, Gentle on Fluids

Crushes off-gassing hypochlorite problems, protects shear-sensitive media, and makes changeovers fast.

- Dry-run capable; valveless (no vapor-lock).

- Stable accuracy ±1–2% in steady state.

- Only tube contacts chem → quick, clean swaps.

See examples & ROI›

Every Transfer Package, Spec’d by James

Transfer mistakes are expensive. James pairs the right technology with the right accessories, verifies NPSH/air curves, and sizes for longevity — so changeouts are planned, not emergency calls.

- Leak risk ↓ >80% moving from sealed units to sealless/diaphragm tech in typical chemical service.

- Service cost ↓ 30–70% using diaphragm/check kits vs. mechanical seal rebuilds.

- Operator time ↓ standardized couplers, quick connects, and clear calibration points.

“We stopped babysitting the skid — it just runs.” — Operations lead, wastewater dosing line

*Typical results in municipal/industrial chemical service; outcomes depend on duty cycle, chemistry, and installation.