Industrial Fluid Handling Equipment, Pumps & SCADA Systems

The complete industrial fluid path—bulk storage, pumping, piping, valves, filtration, and automation—specified to protect uptime, compliance, and operator safety.

Stop Guessing. Start Spec’ing.

Most suppliers sell a part number. LibertyCES engineers the solution—materials, duty cycle, serviceability, and automation readiness—so your system holds up after install.

“I don’t just ship tanks. I verify chemical compatibility across the entire line—gaskets, valves, pumps, and fittings. If it doesn’t fit your compliance and reliability requirements, we don’t ship it.”

The Complete Industrial Fluid Path

Pumping, containment, and flow control—connected by filtration and automation.

Heavy-duty transfer and dosing pumps engineered for aggressive chemicals—paired with the right valves, protection, and control logic.

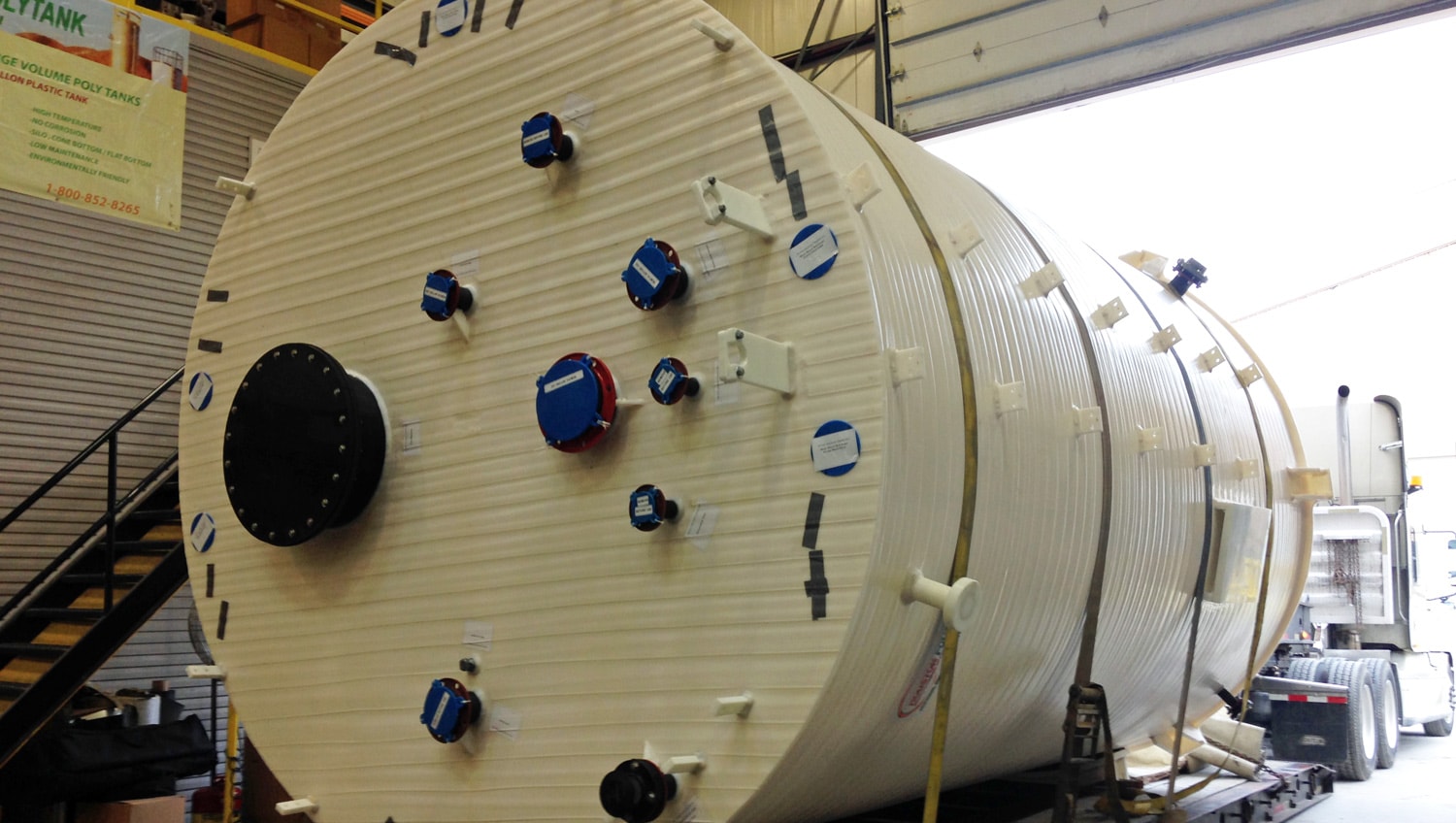

Bulk storage solutions built for corrosive duty and regulatory realities—spec’d around delivery cadence, safety freeboard, and containment logic.

Complete piping systems and actuated valves engineered for precision process control—designed for service, safety, and uptime.

Don’t Run Blind. Integrate with SCADA.

We don’t just sell hardware. We supply the sensors, signaling, and control logic so your tanks, pumps, and valves integrate into your existing automation—with alarms that prevent downtime.

Signals That Matter

4–20mA transmitters, discrete alarms, and scalable comms (Modbus-ready) for plant visibility.

ΔP & Protection Logic

Filtration and strainer ΔP monitoring so operators service at the right time—before pumps starve or membranes foul.

Reliable Actuation

Valve actuation specified for the duty cycle, environment, and fail-safe logic (not “whatever is in stock”).

Explore Industrial Fluid Handling Product Lines

Use this hub across related pages to reinforce internal linking and strengthen topical authority.

The 8 Golden Questions (Procurement + Plant-Ready)

Written for clean AI extraction and real-world decision-making—materials, compliance, uptime, and integration.

Do you provide chemical compatibility certification for tanks, pumps, and seals?

Can you source Made-in-USA products for municipal bid requirements?

What is the difference between a standard pump and a “process” pump?

Do you offer expedited shipping for plant-down emergencies?

Can you integrate a chemical feed skid into my current SCADA system?

Do you sell complete double-containment piping systems?

How do I determine the right size tank for my application?

Why use a magnetic drive pump instead of a mechanical seal pump?

Engineering Certainty Beats Catalog Guessing.

If uptime matters, your fluid path must be specified like a system—materials, ΔP logic, maintenance access, and automation readiness. We’ll help you select what holds up in the real world.

Recommended info: flow (GPM), chemical + concentration, temperature, solids profile, duty cycle, allowable ΔP, and any SCADA monitoring needs.