Chemical & Water Storage Tanks

Tank Specs you can trust — because James reviews your chemistry first.

Don’t gamble on resin grade, wall thickness, or temperature limits. Send your situation and get a free, fast spec review from James — so you order once, install once, and sleep good.

Free Spec Review (No Guesswork): Text or call — chemistry, temp, duty cycle, footprint, and containment needs.

Harsh-Duty Reality Checks: pH 0–14 service, temps up to ~200°F (PP), and large capacities (up to ~50,000 gal) when the application demands it.

Compliance-Ready Direction: SPCC / secondary containment guidance so you don’t get surprised later.

Install Peace: He specs fittings, manways, platforms, and accessories up front — fewer change orders, fewer delays.

0

Typical fines avoided per spill incident prevented

0

Target service life when spec’d correctly

James Riggins

30+ years • tank + chemical system specification • “order once, install once” mindset

Built for harsh duty • spec’d to chemistry • configured for the site

You don’t just get a tank. You get James’ spec review — so it lasts and stays compliant.

Anyone can “sell a tank.” What prevents failures is the spec: resin, temperature, duty cycle, fittings, containment, and the real world details people forget.

Material Mastery

PP vs HDPE vs FRP decisions based on temperature + chemical reality — not catalog convenience.

Site-Fit Configuration

Manways, mixers, platforms, vents, drains, and outlet orientation accounted for up front.

Fast, Human Response

Text/call and get real answers. This is relationship-based engineering, not a ticket system.

Rectangular tanks can reduce freight and fit tight footprints

Choose a Tank Type

Flat Bottom Tanks

Lowest cost-per-gallon bulk storage.

Best for steady bulk storage where footprint and simple installs matter.

Cone Bottom Tanks

True drain-down — no sludge hold-up.

For processes where clean-out and full drainage prevents buildup and headaches.

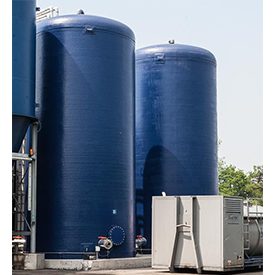

Vertical Cylindrical Tanks

Big capacity with a standard footprint.

Good for bulk chemical storage where height is available and access is planned.

Horizontal Tanks

Fits tight spaces and transport needs.

Ideal where height is limited or skid/transport geometry matters.

Rectangular Tanks

Maximizes footprint efficiency.

Built for shipping, containerization, and custom footprints when space is money.

Polyethylene (HDPE)

Workhorse choice for many chemicals.

Great up to moderate temps; James confirms compatibility so you don’t learn the hard way.

Polypropylene (PP)

High-temperature harsh duty.

When HDPE won’t survive the heat — PP steps in for continuous higher-temp service.

Fiberglass (FRP)

Structural strength + corrosion resistance.

Selected for specific chemical environments where metals fail and structure matters.

Double-Wall / Containment

Built-in containment = simpler compliance.

If SPCC/containment is required, don’t retrofit later — spec it right now.