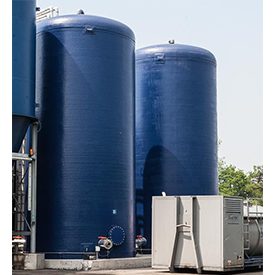

Fiberglass (FRP) Tanks — Built for Tough Environments, Engineered to Last.

Leak-proof storage. Certified standards. Lightweight strength. James Riggins specifies ASTM D3299 filament-wound FRP with the right resin system & corrosion barrier to stop wicking, resist chemical attack, and survive seismic loads.

The James Factor: FRP That Doesn’t Blister, Weep, or Fail Audits

Failures come from wrong resin/liner and inconsistent lay-up. James specifies filament winding for hoop strength and a C-Veil (or synthetic veil) corrosion barrier matched to your MSDS and temperature.

Related systems: Monitoring & Automation · Chemical Feed Skid Systems · Chemical Transfer Pumps

FRP Configurations: Built for Your Footprint

Vertical Flat / Cone Bottom: Industrial standard with massive hoop strength. Open or closed tops; manways and nozzles to spec.

Double-Wall FRP: For hazardous chemicals where berms are impractical. Interstitial monitoring ports available.

Underground Wastewater: Non-reactive to sewer gases (H2S); engineered for soil loads.

Fire Water / Potable Dual-Use: One corrosion-immune vessel for NSF-61 water and fire reserves.

Need pumps or controls, too? We integrate Transfer Pumps and Feed Skids directly at the outlet.

Custom Fabrication & Horizontal Tanks

For height-restricted rooms or mobile systems, we spec horizontal tanks with domed/dished ends and engineered cradles. Ideal for agriculture and skid-mounted duty.

- Domed/Dished Ends for strength

- Internal Baffles for surge control

- Custom nozzles, manways, ladders & platforms

Applications: Where FRP Beats Steel & Poly

Engineered resin/veil systems deliver durability where metals pit and basic plastics creep or craze.

The Bottom Line: Leak-Proof, Audit-Ready, Long-Life

Talk to James — Get the Right Fiberglass Tank.

One Liberty spec can save $20k+ in avoided errors. Match resin, veil, wall schedule, and anchors to your chemistry, temperature, and site.

*Availability of NSF/ANSI 61, AWWA options, and specific calcs varies by vendor/model. We’ll confirm at spec.

FRP Tank FAQ

Why choose FRP over stainless steel?

FRP is immune to electrochemical corrosion, installs faster (lighter weight), and resists chloride attack that pits many stainless grades.

Filament wound vs. hand lay-up?

Filament wound (ASTM D3299) uses continuous glass strands and controlled winding for structural hoop strength. Hand lay-up (ASTM 4097) is labor-intensive and used for certain geometries/liners.

Potable water and fire reserve in one tank?

Yes—when specified with NSF/ANSI 61 compliant resins and the right gelcoat. We’ll confirm resin system and labeling at submittal.

What about UV exposure?

We specify a UV-stabilized gelcoat to prevent fiber bloom and preserve appearance and integrity for decades outdoors.