HDPE Chemical Storage Tanks — Material-Mastered, Not Catalog-Guessed.

High-Density Linear Polyethylene (HDLPE) tanks engineered by James Riggins for about 95% of industrial and municipal chemicals. From extrusion-wound rectangular tanks that never bulge to double-wall sulfuric acid systems and vented tanks for chemical storage, every spec is tuned to the chemistry, temperature, and duty cycle.

If you searched for "Sodium Hypochlorite storage tank specifications", "HDPE tank temperature limits", or "double wall sulfuric acid tank", this is the page James wrote for you.

The Riggins Multiplier: HDPE That Doesn’t Bulge, Crack, or Implode.

Most HDPE tank failures are not “material problems” — they are spec problems. Wall too thin. SG too low. Wrong resin for the temperature. No venting. Rigid pipe glued to a flexing wall. The Riggins Multiplier is James’ 30+ years of field experience applied to every decision: whether HDPE is right at all, and how to make it last 20+ years instead of five.

Related systems: Monitoring & Automation · Chemical Feed Skid Systems · Chemical Transfer Pumps

HDPE Tank Types: Extrusion-Wound Muscle + Rotational Workhorses.

1. Extrusion-Wound HDLPE Tanks (High-Performance)

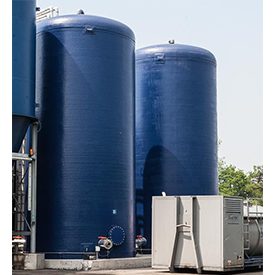

For the harshest duties, James specifies extrusion-wound HDLPE tanks primarily from Houston PolyTank. Material is extruded around a mandrel, building up controlled wall thickness in inches instead of just millimeters.

- Wall Thickness: heavy-duty walls (often ½" and up) matched to SG and duty.

- Structural Integrity: no “elephant feet” radius collapse when tanks are filled and emptied frequently.

- Capacities: from small day tanks to massive vessels approaching 50,000 gallons.

- Field Repairability: weldable and repairable in the field, unlike most XLPE tanks.

This is the upgrade path when you’re tired of replacing thin roto-molded tanks every few years.

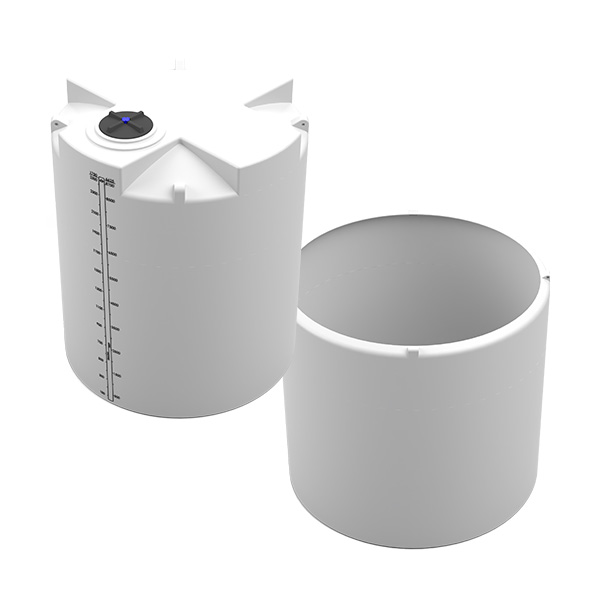

2. Rotational Molded HDPE & XLPE Tanks (Standard Industrial)

For standard bulk storage, James uses rotational-molded tanks from Snyder Industries, Norwesco, and Peabody Engineering — but with spec discipline.

- Construction: one-piece seamless shells with cylindrical, horizontal, and cone-bottom options.

- Resins: HDLPE (linear) for NSF/ANSI 61 and recyclability; XLPE (cross-linked) where extra stress-crack resistance is required.

- Specific Gravity: heavy-duty 1.9 SG ratings for sulfuric acid (~15 lb/gal) and dense brines.

- Geometries: vertical, horizontal leg, cone-bottom, and underground configurations sized up to tens of thousands of gallons.

HDPE here is not “commodity plastic” — it’s engineered storage that fits your site, your freight, and your chemistry.

Configurations: Don’t Ship Air. Don’t Leave Sludge. Don’t Forget the Piping.

HDPE is just the start. Layout, geometry, and containment are where you capture freight savings, clean drains, and true compliance.

Standard for bulk storage up to 50,000 gallons.

110% containment without concrete dikes, using SAFE-Tank® and Captor®-style systems.

Custom rectangular HDPE and PP tanks that fit inside standard shipping containers — don’t ship air, ship product.

Steep-sloped cone bottoms with proper outlet design for 100% drainage of sludge and slurries.

Engineered for burial loads, mobile skids, and truck/rail integrations.

Vented tank designs, flexible connectors, and full nozzle schedules — not bare shells.

Double-Wall HDPE & XLPE Systems (SAFE-Tank®, Gemini², Captor)

For sulfuric acid, bleach, and other high-risk chemicals, James often specifies double-wall HDPE or XLPE tanks instead of freestanding single-wall tanks and concrete berms.

- SAFE-Tank® by Poly Processing: integral outer tank for 110%+ containment.

- Snyder Captor® Double-Wall: industrial verticals with built-in secondary containment.

- Peabody Gemini²™: compact dual-containment systems ideal for day tanks and smaller duties.

Liberty treats tanks, containment, and piping as a single system — so “double-wall” doesn’t stop at the tank shell.

Critical Engineering: Venting, Flex, and Restraint — The Hidden Failure Points.

James’ record of zero spec failures isn’t magic; it’s a checklist. Most HDPE failures happen in the parts people don’t see in the catalog photo.

Vent size and style are matched to pump-in and pump-out rates so tanks don’t implode or burp fumes.

No rigid pipe glued to a flexing wall. Expansion joints and flex hose absorb movement and thermal growth.

Anchors, hold-downs, and restraint rings tuned to local codes — especially in seismic regions like California.

Pre-planned nozzles for level transmitters, leak detection, and SCADA-ready monitoring.

Tanks paired with chemical feed skids and transfer pumps on one engineered drawing.

Submittals, torque specs, and install guidelines to keep warranties intact and inspectors satisfied.

Key HDPE Manufacturing Partners (Specified by Liberty).

LibertyCES doesn’t “push brands.” We match the right manufacturer to the job — extrusion-wound for the harshest duties, rotational for standard storage, and dual-containment when regulations demand it.

Houston PolyTank

Houston PolyTankExtrusion-wound HDLPE & PP

Poly Processing

Poly ProcessingSAFE-Tank® double-wall XLPE

Snyder Industries

Snyder IndustriesVertical & Captor® double-wall

Norwesco

NorwescoAg & industrial HDPE

Peabody Engineering

Peabody EngineeringProChem® tanks

Peabody ProChem Plus

Peabody ProChem PlusUpgraded containment

Where HDPE Makes Sense (and Where James Switches You to PP or FRP).

HDPE is powerful — but it’s not invincible. James’ value is knowing when to use it and when to step up to polypropylene or FRP.

The Bottom Line: The Right Plastic, in the Right Window, with the Right Engineering.

Talk to James — Decide If HDPE Is Really the Right Call.

One Liberty spec can prevent a six-figure failure. James will tell you when HDPE is perfect — and when you need Polypropylene or FRP instead.

Talk to James Request an HDPE Spec

*HDPE temperature limits are general guidelines. Final resin and material selection are confirmed against your exact process conditions.

HDPE Tank FAQ

What is the temperature limit for HDPE tanks?

As a design guideline, High-Density Linear Polyethylene (HDLPE) tanks are used up to about 120°F. Above that, James typically shifts the spec to Polypropylene (180–200°F) or FRP so the tank doesn’t warp or soften. The precise limit is confirmed against your SDS and process data.

Can you repair a cross-linked polyethylene (XLPE) tank?

XLPE tanks are generally difficult to weld once cured, so repairs are limited. One advantage of extrusion-wound HDLPE tanks is that they are weldable and repairable in the field, extending service life and reducing total cost of ownership.

What’s the difference between extrusion-wound and rotational molded HDPE?

Rotational molding creates one-piece, seamless tanks — ideal for many standard storage needs. Extrusion-wound HDPE builds heavy walls in controlled passes, delivering higher structural strength and eliminating the “elephant foot” effect where thin tanks bulge or crack at the radius under cyclic loads.

Do I still need a vented tank for chemical storage if I have double-wall containment?

Yes. Double-wall addresses leak containment, but venting protects the tank from implosion or over-pressure. James sizes vent capacity to exceed pump-out rates and considers the specific chemical (like bleach) to manage fumes and off-gassing.

Can Liberty integrate pumps, skids, and controls with the tank?

Yes. Liberty routinely integrates transfer pumps, chemical feed skids, and monitoring & automation into a single engineered system with one set of submittals.