Polypropylene Tanks — Built for Heat, Built for Aggressive Duty

When heat, oxidizers, and caustics push HDPE and XLPE past their limits, James specs extrusion-wound polypropylene. Walls up to 3.5", service temps to 200 °F water / 180 °F chemicals, and chemical immunity from pH 0–14.

The Case for Polypropylene

Polypropylene is not a commodity tank material. James only specs PP when failure with HDPE, XLPE, steel, or FRP would be catastrophic — high temperature, aggressive chemistry, or both.

- High-temp performance: rated up to ~200 °F water / 180 °F chemicals — where HDPE and XLPE soften, warp, or creep.

- Chemical immunity: compatible across the full pH spectrum (0–14) for sulfuric, hydrochloric, nitric, sodium hypochlorite, caustic soda, and mixed waste streams.

- Extrusion-wound structure: solid walls up to 3.5" thick, no “elephant’s foot” bulging from frequent fill-and-drain cycles.

- Longevity & repairability: 20–30+ year life in service, with weldable walls that can be modified or repaired in the field instead of scrapping the tank.

- Zero fibers, zero pigments: natural PP wall means no glass fibers or colorants shedding into high-purity or critical process streams.

- German DVS 2205 engineering: designed to stringent thermoplastic standards, not generic “good enough” catalog ratings.

When you’re seeing any of these failure modes, you’re in polypropylene territory:

- Sidewall bulging or “elephant’s foot” on HDPE/XLPE day tanks.

- FRP blistering / resin crazing after a few years of hot oxidizer service.

- Steel or stainless pitting and chloride stress cracking around nozzles.

- Temperature-creep failures on tanks rated only for ~120–150 °F.

- Unrepairable XLPE cracks where the only answer is “buy a new tank.”

Heat & Chemistry Envelope

Simple rule: when temperature and chemistry go hostile at the same time, it’s time to spec polypropylene.

Heat Band — HDPE vs XLPE vs Polypropylene

When process temperature climbs past 150 °F, you are beyond XLPE’s comfort zone.

When heat rises, PP survives.

Chemistry Envelope — Typical Polypropylene Duties

- Sodium hypochlorite (NaOCl) 12–15%: hot day tanks and bulk storage where oxidizer attack destroys FRP liners and stainless.

- Sulfuric acid (H₂SO₄): from dilute to strong, including high-temp scrubber and pH-adjust systems.

- Caustic soda (NaOH): high-temperature CIP and aggressive clean-in-place loops.

- Mixed industrial waste & leachate: variable pH, organics, and oxidizers that demand full pH 0–14 compatibility.

- High-purity process streams: where zero fibers, zero pigments, and zero contamination are required.

James designs the tank for your actual chemistry, not just a generic “chemical tank” label.

Where Polypropylene Outruns Steel, FRP & Roto-Molded Plastics

Liberty doesn’t guess at materials. Each spec is reverse-engineered from fines, shutdowns, and field failures James has seen in California’s toughest plants.

| Tank Material | Typical Temp Limit | Chemical Resistance | Wall / Structure | Repairability | Expected Life* |

|---|---|---|---|---|---|

| Painted Carbon Steel | Up to ~140 °F (with liner) | Coating-dependent; vulnerable to under-film corrosion | Welded steel + coatings | Structural repairs possible, coating failures recurring | 5–10 years (repaint / reline cycles) |

| Stainless Steel | High-temp capable | Good, but chloride stress cracking & pitting with many chemicals | Welded metal | Repairable, but expensive and not always compatible with chemistry | 10–20 years |

| FRP (Fiberglass) | Up to ~180 °F (resin-dependent) | Good on paper; real-world blisters, wicking, delamination | Resin + glass fibers; laminate layers | Difficult; many failures are terminal | 7–15 years |

| Roto-Molded HDPE / XLPE | HDPE ~120 °F, XLPE ~150 °F | Good for many ambient-temp chems; limited with hot oxidizers | Seamless shell, thinner walls (bulging risk) | XLPE generally not weldable; replacement is typical | 7–15 years |

| Extrusion-Wound PP | 200 °F water / 180 °F chemicals | pH 0–14 immunity for acids, caustics, oxidizers | Spiral-wound walls up to 3.5", DVS 2205 design | Fully weldable & field-repairable | 20–30+ years with proper design |

*Typical ranges — actual life depends on design, installation, and operating conditions.

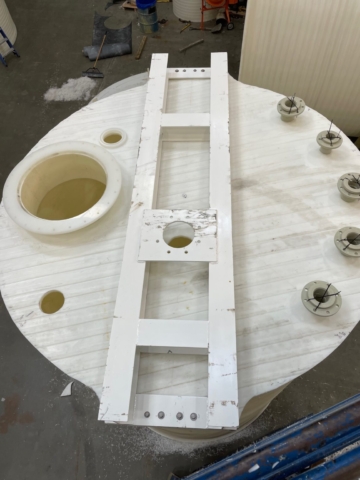

Design Options — Spec’d to Your Application

Cylindrical or rectangular, open or closed top, cone or flat bottoms — Liberty builds PP tanks around your process, not the other way around. James uses extrusion-wound geometry so mixers, ladders, heaters, and handrails are structurally supported by the wall — not hung on hope.

Heavy mixer mounts, no external frames

Heavy mixer mounts, no external frames

Side manways for safe inspection

Side manways for safe inspection

Immersion heaters for hot duty

Immersion heaters for hot duty

Ladders, cages & OSHA handrails

Ladders, cages & OSHA handrails

The Liberty CES Advantage — James’ Spec, Not Just a Tank

Liberty is not a catalog. Every polypropylene tank James signs off on is part of a system — pumps, valves, instrumentation, secondary containment, and compliance all considered together.

- Failure-proof by design: every spec is reverse-engineered from fines, shutdowns, and failure reports James has seen in municipal and industrial plants.

- Invisible risk transfer: EPA, OSHA, and state water board exposures are engineered out of the system up-front instead of left as operator risk.

- Integration with pumps & controls: PP tanks are paired with the right chemical feed pumps, valving, and level/overflow monitoring — not bolted on later.

- Documented justification: when you present Liberty’s spec package, it reads like a risk mitigation plan, not a parts list.

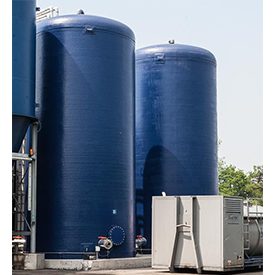

Real Polypropylene Tanks — Not CAD Renders

The tanks Liberty specifies are built by proven manufacturers using extrusion-wound PP and tested against real plants, real chemicals, and real heat — not just lab conditions.

Polypropylene mix tank

Polypropylene mix tank

Natural PP cylindrical tank

Natural PP cylindrical tank

4,900 gal PP tank

4,900 gal PP tank

Rectangular PP for tight footprints

Rectangular PP for tight footprints

Where James Specs Polypropylene

Talk to James — Get the Right Polypropylene Tank.

Start with your worst failure story. James will spec the extrusion-wound PP tank that doesn’t repeat it — matching resin, wall schedule, anchors, and monitoring to your chemistry and temperature.

Actual limits and wall schedules depend on your exact design, chemistry, and duty cycle. We’ll confirm at spec and submittal.

Polypropylene Tank FAQ

What is the temperature limit for Liberty’s polypropylene tanks?

Liberty-specified extrusion-wound PP tanks are typically rated for continuous service up to 200 °F for water and 180 °F for harsh chemicals, depending on the exact design and chemistry. That’s significantly higher than HDPE (~120 °F) or XLPE (~150 °F).

Can polypropylene tanks store sulfuric acid and sodium hypochlorite safely?

Yes. Polypropylene offers chemical resistance across the full pH 0–14 range, making it a strong choice for sulfuric acid, sodium hypochlorite, caustic soda, and other aggressive reagents — especially when heat is involved. James will confirm compatibility for your exact concentration, temperature, and duty cycle.

How is an extrusion-wound PP tank different from a roto-molded tank?

Roto-molded tanks are formed in a single mold and tend to have thinner, less uniform walls. Under aggressive duty they can bulge, creep, and crack — and XLPE versions are generally not weldable or repairable.

Extrusion-wound tanks build up the wall in controlled layers, with solid 3D-wound structure up to 3.5" thick. The result is higher hoop strength, better dimensional stability, and a weldable wall that can be repaired or modified instead of scrapped.

When should I choose polypropylene instead of FRP or stainless?

James typically recommends PP when you have a mix of high temperature + harsh chemistry and need:

- Full pH 0–14 resistance with hot oxidizers or caustics.

- Zero fibers, zero pigments, and low extractables (no FRP glass or resin concerns).

- Field-repairable walls and no reliance on liners or coatings.

- Life-cycle cost that beats frequent FRP relines or metal tank replacement.

How do I get a polypropylene tank properly sized and spec’d for my plant?

Start by sending James your process conditions — chemical, concentration, temperature, flow, duty cycle, and any site constraints. He’ll size the tank, specify nozzles, ladders, mixers, level instruments, and secondary containment, and coordinate with your civil/structural team so the spec holds up in the field.