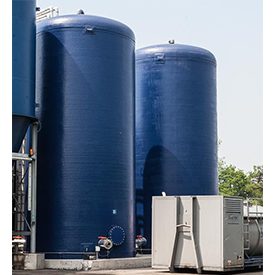

Vertical Cylindrical Tanks — Lowest Cost per Gallon. Safest General Storage.

50–50,000+ gallons. pH 0–14. From extrusion-wound PP (up to 200°F) to roto-molded HDPE/XLPE, a James Riggins–spec’d vertical pairs resin, wall logic, restraints, fittings, and venting so you avoid bulge, cracks, and compliance misses—and get a 20+ year life.

The James Factor: Vertical Specs That Pass Audits & Don’t Fail in the Field

James matches construction method (extrusion-wound vs. roto-mold), resin, wall rating, restraint kits, fittings, flex piping, and venting so your tank runs for decades—and stays in compliance.

Related systems: Monitoring & Automation · Chemical Feed Skid Systems · Chemical Transfer Pumps

Construction Methods: Extrusion-Wound vs. Roto-Molded

Extrusion-Wound (Houston PolyTank): rigid cylinder with uniform wall from top to bottom—no bulge on fill/empty, on-site repairable, ideal for high duty cycles and high temperature (PP to 200°F water).

Roto-Molded (Snyder/Poly/Norwesco/Ace): seamless HDPE/XLPE with stratified wall (thicker at base). Add SAFE-Tank® for 110% containment or IMFO® for full-drain purity.

Need pumps or controls too? See Chemical Transfer Pumps and Monitoring & Automation.

Applications & Industries

We spec verticals wherever reliable bulk storage beats batch drain-out needs—and where long life, compliance, and clean handling are essential.

The Bottom Line: Lower TCO, Clean Audits, Long Service Life

Get the Right Vertical Tank, Guaranteed.

Avoid guesswork. Get a free consult with James Riggins to match construction method, resin, wall rating, restraints, fittings, and venting to your exact duty cycle.

Vertical Cylindrical Tank FAQ

When should I use a vertical vs. a cone bottom tank?

Choose a vertical for bulk storage and lowest cost per gallon. Choose a cone bottom when 100% drain-out is critical (purity, sludge, fines) to avoid residue and cleanouts.

What is an extrusion-wound tank?

Extrusion-wound cylinders are built by extruding PP/PE around a mandrel, creating a uniform wall from top to bottom. This resists base bulge (“elephant foot”), supports high duty cycles, and can be repaired on site.

What is the “elephant foot” failure on poly tanks?

It’s the bulge and stress cracking near the base of some verticals due to hydrostatic head and cycling. James specifies extrusion-wound builds or correct wall ratings and restraints to prevent it.

Why is venting so important?

Undersized vents collapse tanks during fast pump-out or over-pressurize on rapid fills. James sizes PV vents to your rates and integrates scrubbers without restricting airflow.

HDPE vs. XLPE vs. PP — which should I choose?

HDPE is the value workhorse at ambient. XLPE boosts stress-crack resistance for aggressive oxidizers/compliance builds. PP handles higher temperatures (~200°F water/180°F chemicals). James matches resin to chemistry, temperature, and SG.

Can Liberty integrate pumps, skids, and monitoring?

Yes. Liberty provides single-point accountability—tanks, feed skids, transfer pumps, and SCADA-ready controls—all spec’d by James.