Chemical infrastructure for high-purity magnetics manufacturing.

DVS 2205-style extrusion-wound HDPE & PP tanks engineered for new Southeastern magnetics facilities running aggressive commissioning schedules, Nickel Sulfamate plating chemistry, rare-earth slurry mixing, and wetlands-adjacent SPCC requirements.

High-Purity Magnetics Tank Architecture for Fast-Track Expansions

This cinematic sequence walks a rare-earth magnet & advanced materials team through the three silent tank-farm failure modes—lead-time collapse, chemistry contamination, and structural mixer loads—and shows how a Houston PolyTank extrusion-wound PP system turns the tank farm into the strongest link on a high-spec magnetics campus.

Magnetics-grade chemistry vs commodity tanks

High-coercivity rare-earth magnets demand chemistry that stays pristine and mechanical loads that stay locked down. This is the gap between a generic fiberglass tank farm and an extrusion-wound polypropylene architecture built specifically around high-value magnetics lines.

What fiberglass tanks do to high-value chemistry

Resin systems, glass fibers, pigments, and structural creep turn an ordinary FRP tank into a silent liability for high-purity nickel sulfamate and rare-earth circuits.

- Pigments, glass fibers, and resin leach directly into tight-tolerance plating chemistry.

- Surface roughness, discoloration, and pigment bleed translate into pitting, scrap, and rejected magnet batches.

- Nozzle welds crack under mixer loads while “elephant footing” at the base shifts platforms and access steel.

- Inspections and repairs compete with production outages and commissioning windows.

Extrusion-wound PP tanks built around magnetics lines

Houston PolyTank’s extrusion-wound polypropylene vessels remove the chemistry and structural weak points at the tank farm— so the plating line and expansion schedule stay locked in.

- Virgin PP shell with zero pigments, zero fibers, and zero plasticizers for ultra-clean nickel sulfamate and rare-earth chemistry.

- Monolithic, extrusion-wound wall eliminates creep, glass fiber bloom, and resin matrix failures at the shell.

- Integrated 1-ton mixer support welded into the tank wall—no external steel gantries or improvised structures.

- Factory-integrated secondary containment options simplify SPCC at dense tank farms serving new magnetics buildouts.

- 4–6 week U.S. manufacturing lead times that protect commissioning dates instead of pushing them out.

Build the Tank Farm Into the Critical Path, Not After It

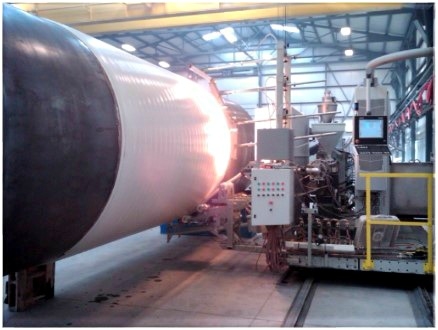

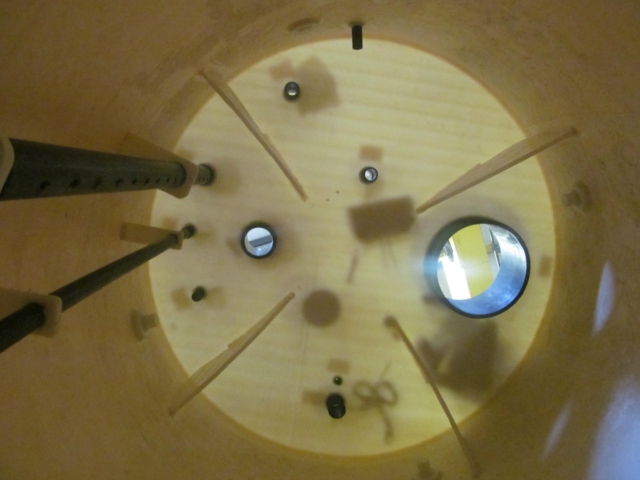

Plating chemistry, cooling water, process gases, and high-torque mixers all converge at the tank yard. These three views show how the tank farm locks into the manufacturing line, the expansion footprint, and the utilities that keep it on schedule.

Tip: Click each image to open the details for that step.

Inside the Line — Where Chemistry Lives

High-density presses, furnaces, and plating cells are built for magnetics-grade stability. If the storage feeding those circuits sheds pigments, fibers, plasticizers, or resin by-products, nickel sulfamate and other tight-tolerance chemistries won’t stay in spec. Clean, virgin polypropylene tanks keep the chemistry as stable as the line itself.

Expansion Zone — Footprint Locked In

The expansion footprint is already carved out. Tank yard, wastewater treatment, HazMat, and chiller areas are fixed on the site plan. The only thing left to decide is whether the tank farm helps your team beat the schedule—or becomes the quiet civil bottleneck that pushes the line by a quarter.

Tank Farm Blueprint — Every Square Foot Accounted For

The site plan ties the manufacturing facility to wastewater, HazMat, solids handling, a dedicated chiller yard, and a tank yard reserved for process gases and critical chemistries. Houston PolyTank shells drop into that layout without berm delays, external mixer gantries, or last-minute structural redesigns at 90% design.

When the tank farm can’t fail quietly, bring in the tank guy.

Rare-earth magnetics, advanced materials, and other high-spec lines don’t leave much room for “good enough.” Houston PolyTank’s extrusion-wound shells give you clean, repeatable storage — and James helps line that hardware up with the real-world constraints of your project: civil, structural, safety, and commissioning dates.

Houston PolyTank details that actually show up on site