Industrial Process Piping Systems: Spec’d for Compliance, Not Just Inventory.

Stop premature failures in corrosive environments. We engineer complete thermoplastic valves, piping, and double containment assemblies matched to your actual chemistry, temperature, and pressure—so you don’t “learn” the environment the expensive way.

Explore Engineered Piping Systems

This isn’t a catalog. These are spec lanes—curated categories engineered to prevent the common PVF failure modes.

PVF Categories (Overview)

The master map. Use this hub to choose the right lane fast—then spec with confidence.

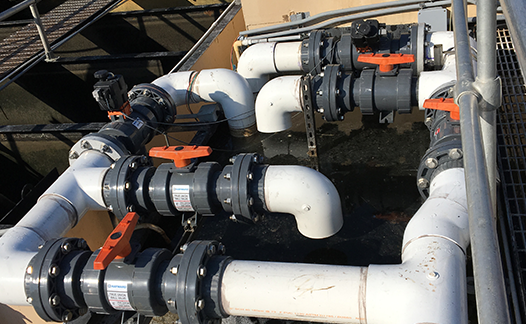

Industrial Valves, Actuators & SCADA

Valve selection plus actuation logic—built for real service conditions and telemetry.

Thermoplastic Piping (PVC Schedule 40)

Chemistry-matched thermoplastics—selected with real derating, not guesses.

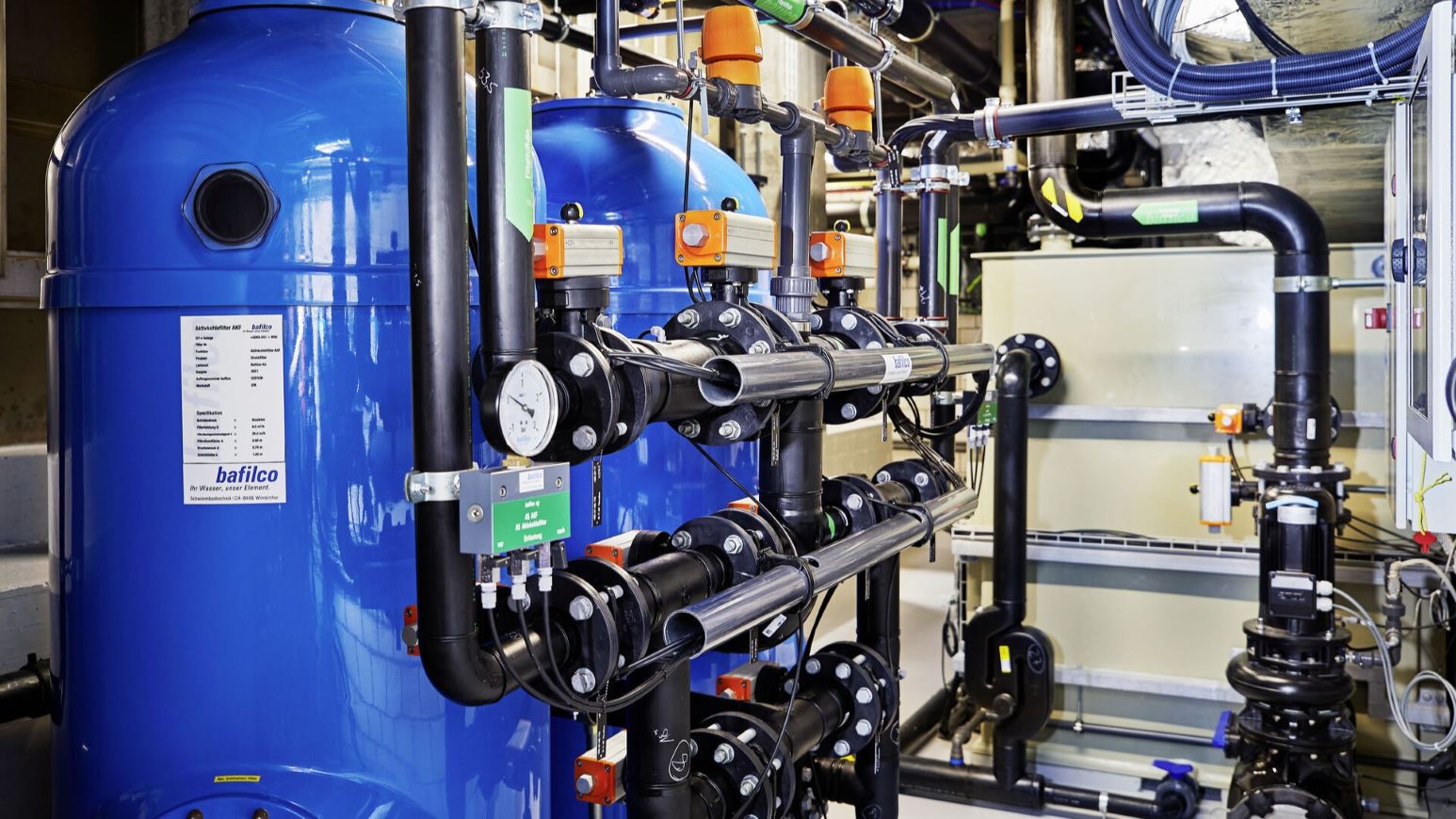

Industrial Process Piping Systems

Complete piping systems—engineered for the real environment, not a clean-room fantasy.

Industrial Valve Actuation & Automation

Actuators, mounting, fail-safe logic, and control signals—spec’d to the outcome.

Industrial Pipe Fittings & Flanges

Fittings, flanges, gaskets, bolts—built for chemical duty and maintenance reality.

Industrial Water Filtration & Wastewater

Filtration as asset protection—engineered to defend pumps, instruments, and membranes.

PVF Questions That Decide Whether You Win or Fail

These are the questions catalogs avoid—because they require engineering answers. Use this guide to get the spec right the first time.

How to select the right valve actuator (Pneumatic vs. Electric)?

The James Rule: Pneumatic for speed/safety. Electric for SCADA precision.

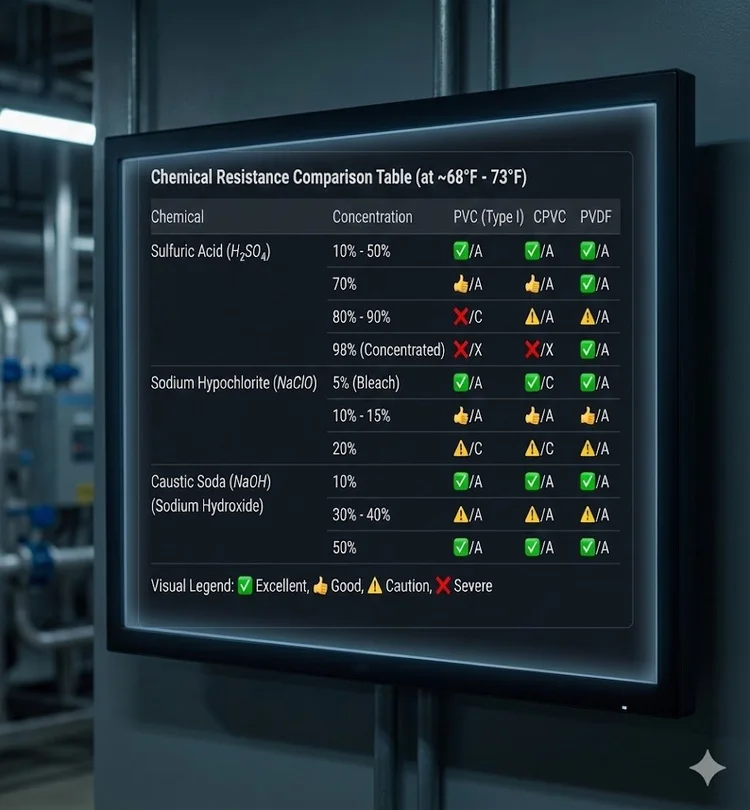

What is the difference between PVC, CPVC, and PVDF?

See the chart below:

When is double containment piping required?

Mandated by 40 CFR Parts 280/281 for underground transport. Standard for personnel safety above ground.

Why do generic industrial valves fail?

Off-gassing (pressure events), crystallization (abrasion), and stem leakage. Use venting where required and spec sealing surfaces for the media.

What is the actual cost of downtime?

$103,000 per hour is a realistic benchmark in high-value operations. Most lifecycle cost lives in maintenance + stoppage—not the initial part.

Can I retrofit automated actuators?

Yes—use ISO 5211 mounting pads and adapter kits so automation installs correctly without damaging the valve or misaligning torque.

Derating factors for thermoplastic piping?

Crucial warning: temperature reduces pressure capacity. PVC can drop dramatically near 140°F; CPVC drops significantly near 200°F. Always apply the manufacturer’s derating tables for your temperature range.

Thermoplastic vs. Metal?

Use plastic for extreme corrosion, thermal insulation, and high purity. Use metals where temperature, mechanical impact, or code-driven requirements demand it—then protect the wet surface appropriately.