THERMOPLASTIC PIPING • SCHEDULE 40 PVC PIPE • PVDF • PP • ECTFE • JOINING TECHNOLOGY

Industrial Thermoplastic Piping & Schedule 40 PVC Systems

Schedule 40 PVC is easy to buy. The hard part is keeping a plastic piping system alive through chemical exposure, thermal expansion, water hammer, and real plant maintenance. LibertyCES helps you spec the system, not just the pipe.

For fast guidance, send: media + concentration, temperature range, operating pressure, and routing (aboveground/underground).

THE “TROJAN HORSE” STRUCTURE (HIGH VOLUME → HIGH VALUE)

Bring Them In With Schedule 40. Keep Them Safe With Engineered Systems.

Many people searching “Schedule 40 PVC pipe” don’t know the failure traps: expansion stress, brittle fracture risk in the wrong service, chemical incompatibility, and poor joining discipline. This page answers the common questions first — then shows when the system should upgrade to PVDF / PP / ECTFE and fusion joining.

Start With the Real Use Case

We treat “PVC pipe” as a starting point — then select the right thermoplastic family based on media, temperature swings, pressure, and what happens if it leaks.

- Water treatment and mild chemical service: PVC/CPVC can be appropriate

- Higher purity or stronger chemical duty: PP or PVDF is often the better move

- High-risk chemicals / gas permeation concerns: ECTFE enters the chat

Join It the Right Way

Joining isn’t a detail — it’s the system. Different plastics require different methods for strength, cleanliness, and long-term maintainability.

- PVC/CPVC: solvent cement systems when appropriate

- PP/PVDF/PE: fusion and welding pathways designed for service

- High-purity: advanced fusion options to reduce internal disruptions

Engineer Against Silent Failures

Thermoplastics move with temperature. If you lock them down like steel, the pipe will “fight back” — stress cracks and leaks show up later when you can’t afford downtime.

- Expansion allowance (guides/anchors, loops, offsets)

- Support spacing aligned to material and temperature

- Water hammer risk awareness and mitigation mindset

Want a fast spec sanity-check?

Send your media, temperature range, pressure, and routing — we’ll guide material + joining + expansion control.

THE VOLUME DRIVERS

Schedule 40 vs Schedule 80 PVC Pipe — Plus Municipal C900 / C905

This is where most buyers start. Here’s the difference that actually matters in the field: wall thickness, pressure handling, and mechanical durability — then where C900 fits for underground municipal mains and fire loops.

Schedule 40 vs Schedule 80 (Practical Differences)

| Topic | Schedule 40 PVC | Schedule 80 PVC |

|---|---|---|

| Wall Thickness | Standard wall | Thicker wall |

| Pressure Capability | Lower than Sch 80 (size-dependent) | Higher than Sch 40 (size-dependent) |

| Mechanical Durability | Good for many applications | More resistant to impact/damage |

| Typical Color | Often white | Often gray |

| When to Choose | General water/mild service when appropriate | Industrial process duty where added strength matters |

Don’t choose by habit. Choose by duty: media, temperature swing, pressure, installation conditions, and the consequence of failure.

Schedule 40 vs C900 (Why They’re Not the Same Job)

Schedule 40 is commonly used in building/process contexts. C900/C905 is commonly specified for underground municipal water distribution where standards, bedding, and installation environment drive the design approach.

- C900/C905 is frequently called out on municipal plans for buried water mains and fire loops

- Selection should align to project specs, trench conditions, and pressure class requirements

- We help you match pipe standard to application — without guessing

Compressed Air Warning

Many facilities and project specs prohibit using PVC for compressed air/gas distribution because failure can be brittle and dangerous. If compressed air is involved, ask for a safer system recommendation matched to your facility standards.

THE PERFORMANCE MATRIX

Advanced Thermoplastic Materials: PVC, CPVC, PP, PVDF, ECTFE

“Thermoplastic” is the category. PVC is one member. When chemical duty, temperature, purity, or permeation risk increases, the system often needs PP, PVDF, or ECTFE — plus a joining method that matches the service.

PVC (Schedule 40 / 80)

A common workhorse for many water and mild chemical applications when used within its limitations. Selection must consider temperature, chemical compatibility, and installation conditions.

- High-volume availability

- Widely specified for many utility applications

- Needs expansion-aware installation discipline

CPVC

Often selected when higher temperature capability is needed beyond standard PVC in compatible services.

- Higher temperature capability vs PVC in many cases

- Common in industrial chemical handling contexts

- Compatibility still depends on the exact media

Polypropylene (PP)

A strong industrial choice for many chemical services with better toughness characteristics than many buyers expect.

- Excellent for many chemical-duty environments

- Often paired with fusion joining methods

- Good option when PVC becomes a limitation

PVDF

Premium thermoplastic used for high-purity and aggressive chemical duty, where surface quality and stability matter.

- High-purity water loops and critical process service

- Strong chemical resistance across many media

- Pairs well with advanced fusion strategies

ECTFE

High-end option when chemical duty and permeation resistance requirements demand a premium thermoplastic.

- Selected for demanding chemical environments

- Used when other plastics become risky

- System-level spec is critical (pipe + valves + seals)

PE / HDPE

Ductile thermoplastic family widely used in many industrial utility and distribution contexts. Selection depends on application and facility standards.

- Often chosen where toughness/ductility is valued

- Common fusion joining pathways

- Verify compatibility and pressure requirements

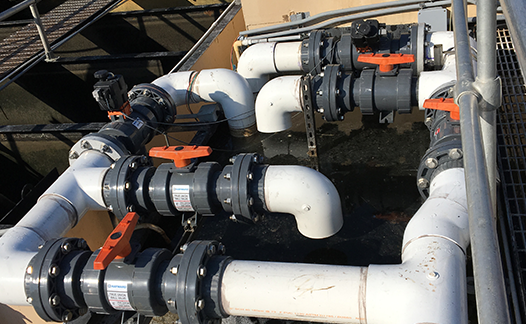

System Components Matter

The best pipe fails with the wrong valve body, wrong seal, or wrong connection strategy. We treat thermoplastic piping as a complete fluid handling system.

- Valve bodies + seats matched to media

- Fittings and joining method aligned to service

- Supports/guides designed for movement

Need the right pick fast?

Send the duty conditions and we’ll recommend the right thermoplastic family and joining pathway.

THE TECH EDGE

Joining Technology: Solvent, Fusion, Welding, IR

Thermoplastic piping succeeds or fails at the joints. We help you choose a joining approach that matches cleanliness needs, service severity, and maintenance reality — not just what’s familiar.

Solvent Cement (PVC/CPVC)

Common for many PVC/CPVC applications when used correctly with the right prep, cure time, and compatible products. Always follow manufacturer instructions for the specific system.

- System discipline matters (prep + cure + compatible components)

- Correct fitting selection for pressure and service

- Temperature swings still require expansion-aware design

Fusion Pathways (PP / PVDF / PE)

Fusion methods create highly consistent joints when executed with the correct equipment and procedures for the material.

- Repeatable joining for many industrial thermoplastics

- Good fit for chemical service and long-term maintainability

- Best results require trained procedures and correct tooling

IR / Advanced Fusion Options

Infrared fusion reduces physical contact heating during the join and is used in applications that value clean, controlled joints.

- High-tech joining strategy for high-purity mindsets

- Designed to support clean internal flow paths

- Selection depends on material, size, and project requirements

Choosing joining method is a spec decision.

If the service is critical, the join must be chosen like an engineered component. Tell us the duty conditions and constraints — we’ll recommend a joining pathway that fits.

THE “JAMES FACTOR” LAYER

Prevent Silent Failures: Thermal Expansion, Support Spacing, Water Hammer

Plastic piping moves with temperature more than steel. If it’s restrained incorrectly, stress concentrates at joints and fittings. This section explains the prevention mindset that keeps thermoplastic systems stable.

Thermal Expansion Control

Expansion isn’t optional — it’s physics. The system must be designed to move intentionally (not randomly).

- Allow movement where needed (guides/anchors placed on purpose)

- Use offsets/loops where routing demands it

- Don’t “clamp it like steel” and expect peace

Support Spacing That Matches the Material

Sag, vibration, and thermal cycling accelerate failures. Supports should be chosen and spaced per the system’s material and service.

- Spacing depends on diameter, temperature, and resin family

- Account for valves and heavy fittings as load points

- Use proper supports that don’t damage the pipe surface

Water Hammer Awareness

Fast valve closure and pump events create pressure transients. A strong material choice can still fail if hammer is ignored.

- Identify transient sources (valves, pumps, fast-acting controls)

- Use system strategies that reduce sudden pressure spikes

- Design like the upset event will happen (because it will)

Want the “why it fails” diagnosis before you build?

Send your conditions and we’ll point to the failure traps and the right upgrades.

FEATURED SNIPPET STRUCTURE

Thermoplastic Piping FAQ (The 8 Questions Buyers Actually Search)

Direct answers first — then the engineering logic that upgrades commodity pipe shopping into an engineered system decision.

1) Is thermoplastic pipe the same as PVC?

Thermoplastic is the broad category of plastics that can be softened and formed with heat. PVC is one specific thermoplastic. So, all PVC pipe is thermoplastic — but many thermoplastic piping systems are not PVC (PP, PVDF, PE, ECTFE).

2) What is the difference between Schedule 40 and Schedule 80 PVC pipe?

The biggest difference is wall thickness. Schedule 80 has a thicker wall than Schedule 40 (size-dependent), which typically supports higher pressure and better mechanical durability. Selection should still consider service media, temperature, and installation conditions.

3) Can thermoplastic piping systems be repaired by welding?

Many thermoplastics (such as PP, PVDF, and PE families) can be repaired or modified with appropriate welding/fusion techniques, depending on the system and manufacturer procedures. PVC/CPVC often use solvent-cement repair methods rather than heat welding.

4) Why is PVC often prohibited for compressed air piping?

Many facilities and specs prohibit PVC for compressed air because failure can be brittle and can create dangerous fragments. If your application involves compressed gas, request a safer system recommendation aligned to your facility standards.

5) What are 3 main types of industrial thermoplastic piping?

A common high-level grouping is: PVC/CPVC (vinyls), Polypropylene (PP), and PVDF — with other premium options (like ECTFE) used when chemical duty or permeation resistance demands it.

6) Why is PVDF used for pharmaceutical or ultrapure water systems?

PVDF is commonly selected for high-purity applications because it supports clean system design, stable material performance, and compatibility needs that exceed many commodity plastics. The exact selection should match the quality requirements of the process.

7) How do you account for thermal expansion in plastic piping design?

You design the system to move intentionally: guide and anchor placement, offsets/loops where needed, and support spacing that matches the resin, temperature, and routing. The key is not over-restraining the line and not ignoring temperature swings.

8) What is the difference between Schedule 40 PVC and C900 pipe?

Schedule 40 is widely used in building and process contexts. C900/C905 is frequently specified for underground municipal water distribution. The correct choice depends on project specs, installation environment, and required pressure class.

SYSTEM SOURCING

Thermoplastic Piping Vendors & System Components

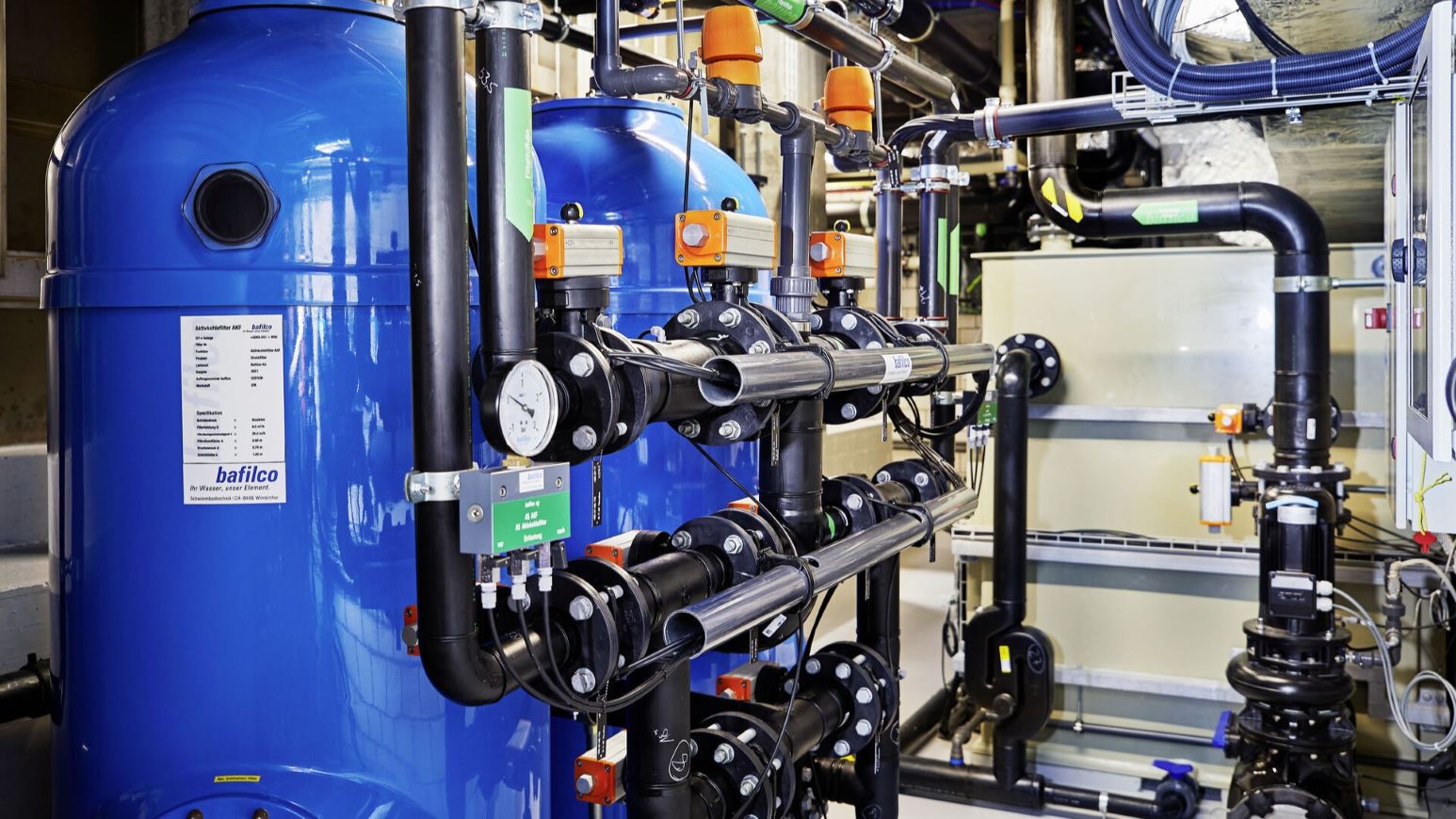

We support thermoplastic piping as a system: pipe + fittings + valves + joining strategy + install discipline. These are common manufacturer ecosystems we integrate depending on duty requirements.

Asahi/America

Broad thermoplastic fluid handling ecosystem for industrial and environmental piping systems.

- Piping families spanning common to advanced chemical duty

- System-level integration (pipe + valves + fittings)

- Joining strategies aligned to service requirements

GF Piping Systems

Precision system approach with strong documentation and joining technology ecosystems used across critical applications.

- Thermoplastic process piping systems

- Joining solutions that support consistency

- High-purity and chemical-duty selection pathways

Hayward Flow Control

Common valve/component integration for aggressive environments where system compatibility is non-negotiable.

- Valve and component integration into thermoplastic systems

- Selection aligned to media and temperature duty

- Ideal when the “component mismatch” is the real failure point

THE CONVERSION LAYER

James Riggins: The Operating System Behind Thermoplastic Specs

Thermoplastic piping is a material science and installation discipline problem. James brings the field pattern recognition that prevents expensive mistakes — before pipe gets cut or fused.

What You Get When You Reach Out

- Material family recommendation based on duty (media + concentration + temperature + pressure)

- Joining method pathway that matches service severity and cleanliness needs

- Expansion control mindset (supports, guides/anchors, routing offsets)

- Component compatibility (valves, seals, fittings) matched to the same duty

- Media + concentration

- Temperature range (normal + cleaning/sanitizing if applicable)

- Operating pressure + known transients (if any)

- Routing: aboveground / underground / trench / rack

- Any facility “do-not-use” lists (materials you must avoid)

BROWSE ALL PIPING & FLOW SUBCATEGORIES

Explore Related Industrial Piping, Valves, Automation & Filtration

Quick jump links to the full subcategory library — consistent internal linking across every page for stronger topical authority.

Piping, Valves & Fittings

Core piping system navigation — specs, sourcing, and integration guidance.

Open page →Industrial Valves, Actuators & SCADA

Valve packages, actuation, and monitoring/control architecture.

Open page →Thermoplastic Piping: PVC Schedule 40 Systems

Schedule 40 PVC through PVDF/PP/ECTFE upgrades and joining strategy.

Open page →Industrial Process Piping Systems

Engineering-first routing, duty-based selection, and reliability execution.

Open page →Industrial Valve Actuation & Automation Supply

Actuators, controls, accessories, and integration support.

Open page →Industrial Pipe Fittings & Flanges Supply

Fittings, flanges, and component ecosystems that match duty and media.

Open page →Industrial Water Filtration & Wastewater Treatment Supply

Filtration, treatment support, and system-level sourcing coordination.

Open page →