PROCESS PIPING • CHEMICAL SERVICE • HIGH-PURITY • COMPRESSED AIR

Industrial Process Piping Systems & Engineered Fabrication

Process piping isn’t plumbing — it’s a safety-critical system governed by design rules, material limits, and installation realities. We help you spec piping that holds up to chemistry, pressure, temperature, and plant uptime demands.

The Code Shield™

The fastest way to burn a project is ambiguity: wrong materials, wrong joining method, or “close enough” pressure design. LibertyCES supports ASME B31.3-informed process piping selection — so the system is engineered for the duty, not the brochure.

Have drawings? Send line list, media, concentration, temperature range, and operating pressure — we’ll recommend the right material + joining method + containment strategy.

SITEWIDE NAVIGATION (CROSS-LINKED ON EVERY PAGE)

Industrial Piping & Flow Systems — Subcategories

Fast internal navigation for engineers: browse adjacent subcategories without hunting menus.

HIGH-INTENT SEARCH HUB

Process Piping for Chemical, High-Purity & Plant Utilities

This page is structured to match how engineers search: materials, failure modes, containment, and code-driven selection.

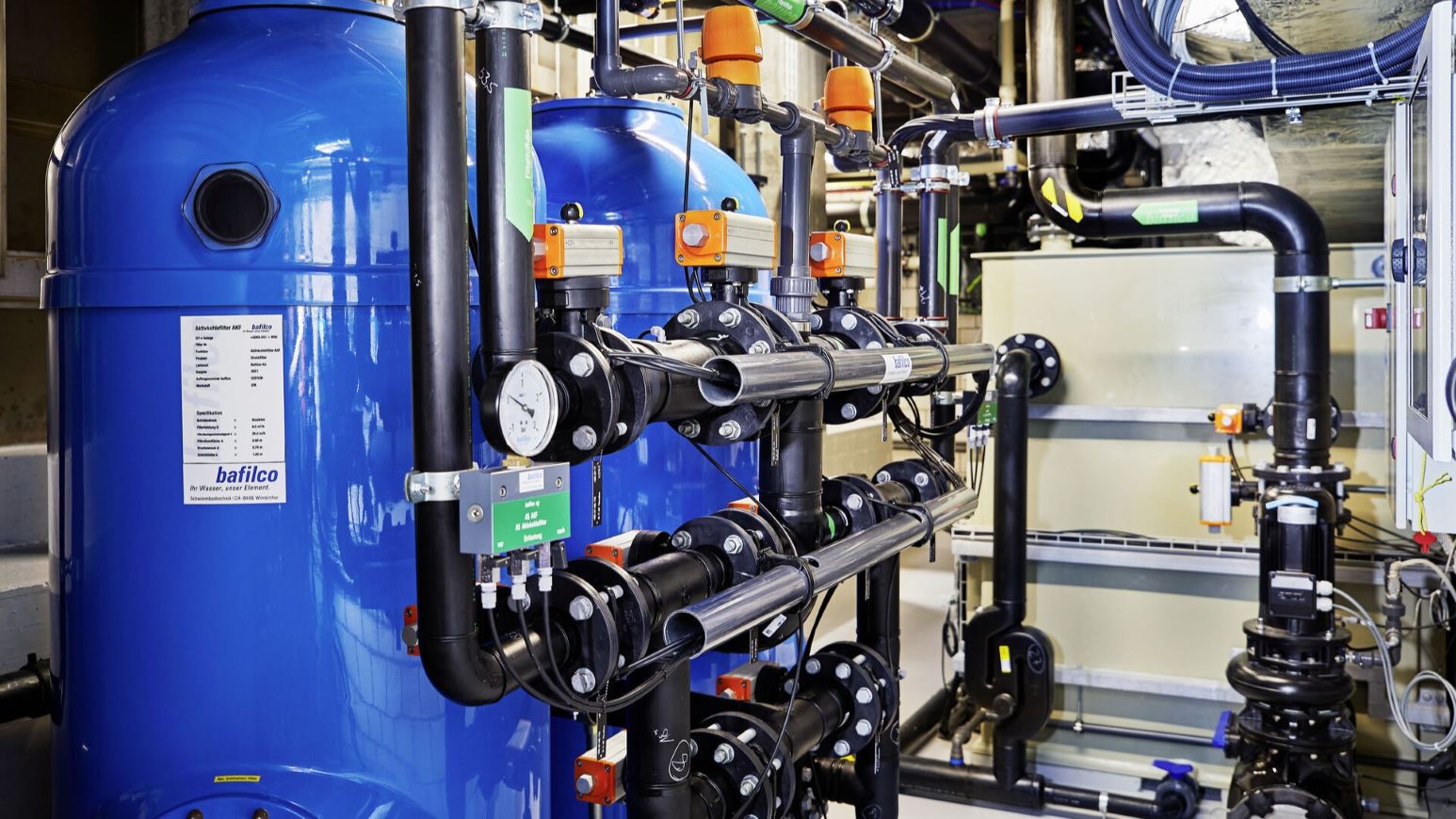

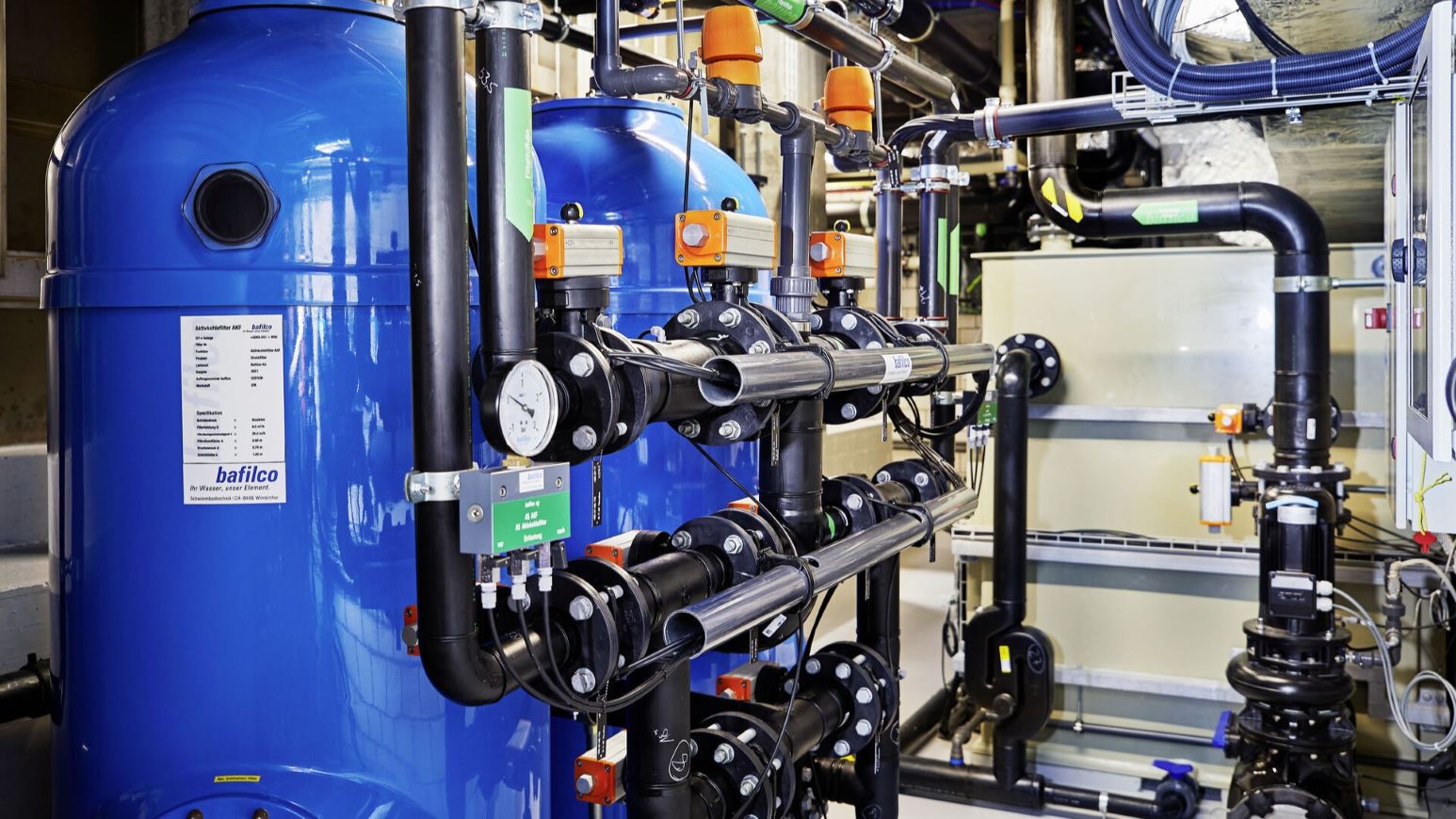

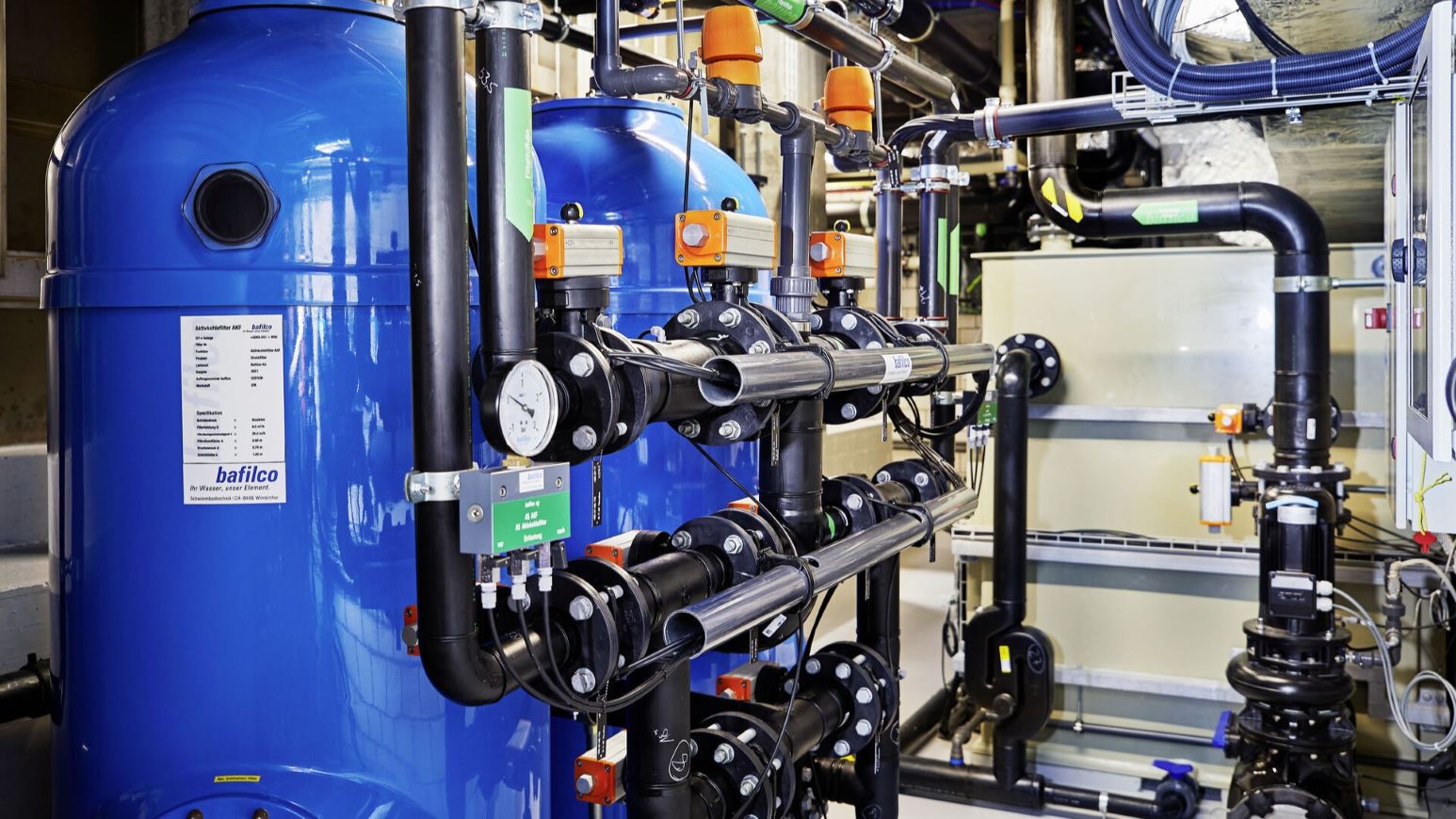

Chemical Process Piping

Corrosive media demands more than “stainless vs plastic.” We align body material + seal strategy + joining method to the actual chemical duty.

- Thermoplastics: CPVC, PP, PVDF (chemistry-first selection)

- Lined options when temperature/pressure exceed plastic limits

- System thinking: pipe + valves + fittings + supports + containment

High-Purity & Clean Environments

High-purity systems are built around contamination control, repeatable joining, and clean routing. The spec needs to match the process and the facility reality.

- Fusion / mechanical joining choices by cleanliness + access

- Routing strategy that protects maintenance and validation

- Documentation-ready selection logic

Compressed Air Piping

Air distribution is a hidden ROI lever: pressure drop, leaks, and corrosion drive energy cost and tool downtime. We support durable, efficient layouts and material choices.

- Layout and component strategy to reduce pressure drop

- Leak control mindset: isolation points + monitoring readiness

- Material choice to avoid rust and contamination issues

MATERIAL SELECTION (WHERE MOST SPECS WIN OR LOSE)

Material Selection for Aggressive Environments

The goal is simple: prevent mismatch failures. We select material and joining method based on chemical compatibility, temperature, pressure, permeability risk, and maintenance realities.

High-Purity Plastics (PVDF / PP / CPVC)

Built for chemical duty where corrosion punishes metals. Ideal for many acids/caustics and clean service when specified within limits.

- PVDF: strong chemical resistance for aggressive duty

- PP: tough, widely used for chemical handling systems

- CPVC: common chemical-service option within temperature limits

Stainless Steel & Alloys

Ideal for many sanitary and high-temperature applications — but not a universal answer. Selection must consider corrosion mechanisms and real operating conditions.

- Pressure + temperature performance for demanding duty

- Traceability mindset for critical service

- Selection must consider corrosion risks in specific chemistries

Compressed Air Distribution

Compressed air is often your facility’s “fourth utility.” Piping choices impact pressure drop, leak rates, air quality, and long-term maintenance.

- Reduce pressure drop with smart routing + proper sizing

- Prevent contamination issues with corrosion-aware materials

- Add isolation points for fast maintenance and future expansion

SCHEDULE & RISK CONTROL

Custom Fabrication, Spooling & Build Strategy

Field welding in a live plant is expensive and risky. Where the project allows, controlled fabrication and spool planning can reduce downtime exposure and improve build consistency.

Off-Site Spool Fabrication

Spooling means assembling pipe sections with repeatable work practices — reducing surprises during install.

- Parallel workstream: fabrication progresses while site is prepped

- More consistent workmanship than “whatever the weather is today”

- Cleaner fit-up and faster tie-ins during shutdown windows

Connection Strategy

Selection isn’t only about chemistry. It’s also about maintenance access, vibration, thermal movement, and whether the plant can actually service the connection type.

- Flanged vs welded vs mechanical joins: chosen by duty + service access

- Support/hanger strategy to prevent stress and movement damage

- Isolation points placed intentionally (not randomly)

LEAK PREVENTION & EARLY WARNING

Double Containment Piping & Leak Detection Pathways

For hazardous chemicals, underground runs, or compliance-driven sites, double containment provides a second barrier plus a pathway to detect leaks before they become an incident.

What Double Containment Does

An inner “carrier pipe” holds the process media. An outer “containment pipe” provides secondary containment, with an interstitial space that can be monitored.

- Reduces soil/secondary impact risk for underground lines

- Supports monitoring strategies that help pinpoint leak events

- Pairs well with SCADA alarm workflows in critical sites

Leak Detection Approaches

Detection varies by application: visual inspection ports, sump monitoring, sensor cable strategies, or measured interstitial events depending on the system type.

- Define “what triggers an alarm” before install

- Plan access points so maintenance can act fast

- Align detection to actual site response procedures

Where It’s Used Most

Double containment is common when leakage has consequences beyond cleanup — safety, compliance, and downtime.

- Underground chemical transfer

- Hazardous process areas and containment-required zones

- Remote sites where early detection prevents big damage

Want to spec containment the right way?

Send media, concentration, temperature, routing (aboveground/underground), and the consequence of leakage. We’ll recommend a containment approach and monitoring pathway that matches the risk.

E-E-A-T SIGNAL (REAL ENGINEERING LANGUAGE)

ASME B31.3 Lens + Selection Checks

B31.3 is the process piping framework engineers use for pressure design, materials, and inspection expectations. We use it as a selection lens so system choices match the duty and risk profile.

Pressure + Temperature Reality

Design pressure is more than “normal operating.” Systems must consider transients, thermal swings, and the real max conditions that show up during upset events.

- Define operating envelope (normal + upset)

- Match pressure class and connection strategy

- Confirm material limitations at temperature

Material Compatibility + Permeation

Chemical service failures usually trace back to compatibility mismatch, permeation risk, or the wrong seal/elastomer selection for the media.

- Compatibility by chemical + concentration + temperature

- Seal/elastomer strategy (not an afterthought)

- Consider permeation risk where it matters

Inspection + Documentation Readiness

The best specs are easy to approve: clear basis of design, clear connection strategy, and clear install expectations.

- Submittal-ready rationale (what/why)

- Defined test expectations by service criticality

- Maintainability planned into routing + access

FEATURED SNIPPET / AI OVERVIEW STRUCTURE

The 8 Questions Engineers Ask Before They Spec Process Piping

Built for fast scanning: Direct Answer → selection logic → practical insight.

1) What is the difference between plumbing and process piping?

Plumbing supports occupancy and hygiene (water supply and waste), while process piping supports manufacturing and chemical processing. Process piping is engineered around the process media, pressure/temperature demands, and safety risk — which typically requires stricter design and documentation discipline than standard building plumbing.

2) What is the best piping material for corrosive chemical plants?

The best material depends on the exact chemical, concentration, and temperature. Thermoplastics (like PVDF/PP/CPVC) often excel in chemical duty, while lined or alloy systems may be needed when temperature/pressure push beyond thermoplastic limits.

- Choose by chemical + concentration + temperature (not by habit)

- Confirm seal/elastomer compatibility for the media

- Consider containment strategy when the consequence of leakage is high

3) Why does ASME B31.3 matter for industrial systems?

ASME B31.3 is a process piping framework used across industrial processing. It helps teams think clearly about pressure design, material limits, connection strategy, inspection expectations, and safety risk — so the piping system is engineered for real operating conditions.

4) Why use aluminum or corrosion-resistant piping approaches for compressed air?

Compressed air performance is won or lost in pressure drop and leaks. Corrosion and internal roughness can increase pressure loss and contaminate downstream tools. Using corrosion-resistant approaches and clean routing helps maintain pressure and air quality.

- Lower pressure drop improves system efficiency

- Corrosion control helps protect tools and valves

- Isolation points simplify maintenance and future expansion

5) How do you detect leaks in underground industrial piping systems?

High-risk underground runs often use double containment with an interstitial space that can be monitored. Detection may be visual (sump/ports) or sensor-based depending on the system type and site requirements.

- Define detection method and alarm logic before installation

- Plan access so maintenance can respond quickly

- Match monitoring to the facility’s actual response plan

6) What are the benefits of off-site pipe spool fabrication?

Spool fabrication reduces install uncertainty by planning and assembling sections in a controlled workflow. It can shorten shutdown windows and reduce fit-up surprises on site.

- More predictable build sequence

- Cleaner tie-ins during limited downtime windows

- Reduced on-site rework and “figure it out in the field” delays

7) When is seamless pipe preferred over welded pipe in industrial applications?

It depends on service criticality, pressure/temperature demands, and project requirements. Some applications prefer seamless pipe for critical mechanical performance and risk reduction, while other services can perform well with properly specified welded pipe.

- Define duty: pressure, temperature, media risk, and consequence of failure

- Align selection to project specs and inspection expectations

- Focus on the system design — not only one component choice

8) Why is insulation critical for process piping efficiency and safety?

Insulation supports process stability and personnel safety. It helps maintain temperature (reducing viscosity issues, freezing risk, or heat loss) and reduces burn hazards on hot lines. The right insulation plan also reduces energy waste.

AUTHORITY LAYER

Meet James Riggins — Spec-Driven, Field-Proven Guidance

LibertyCES is built to prevent costly specification mistakes. We focus on the details that control outcomes: material compatibility, connection strategy, containment planning, and maintenance realities.

What You Get When You Ask for Guidance

- Clarity on material selection (chemical + temperature + pressure)

- Connection strategy aligned to maintenance access and install conditions

- Containment and monitoring guidance for high-consequence lines

- Spec language that reads clean in submittals

- Media + concentration

- Temperature range

- Operating pressure + any upset/transient expectations

- Routing (aboveground/underground) + containment expectations

- Drawings or a basic line list (if available)