Command Your Flow: Industrial Actuation & Severe Service Valves

From slurry to steam—custom valve + actuator packages specified by James Riggins for the $103,000/hour moment. Stop buying parts. Start engineering outcomes.

The “James Factor”: The Human Operating System

In flow control, the failure is rarely “the valve.” It’s almost always a spec mismatch: wrong elastomer for chemical concentration, wrong seat for thermal cycling, wrong torque margin for sticky media, or an actuator that stalls at end-of-travel.

Zero Spec-Failures (Real Field Data)

James Riggins isn’t a catalog clerk—he’s a technical authority who translates manufacturer data into field reality. He has personally specified 100+ municipal and industrial projects with a record of zero spec failures. His advantage is 30+ years of field memory—what survives corrosive rooms, wet vaults, and harsh duty cycles.

Economic Shield: $103,000/Hour Downtime Risk

Unplanned downtime is expensive, public, and avoidable. James specs extend valve life 2–3× by matching chemistry, pressure, temperature, and cycle rate—and building correct safety margins for actuation and sealing.

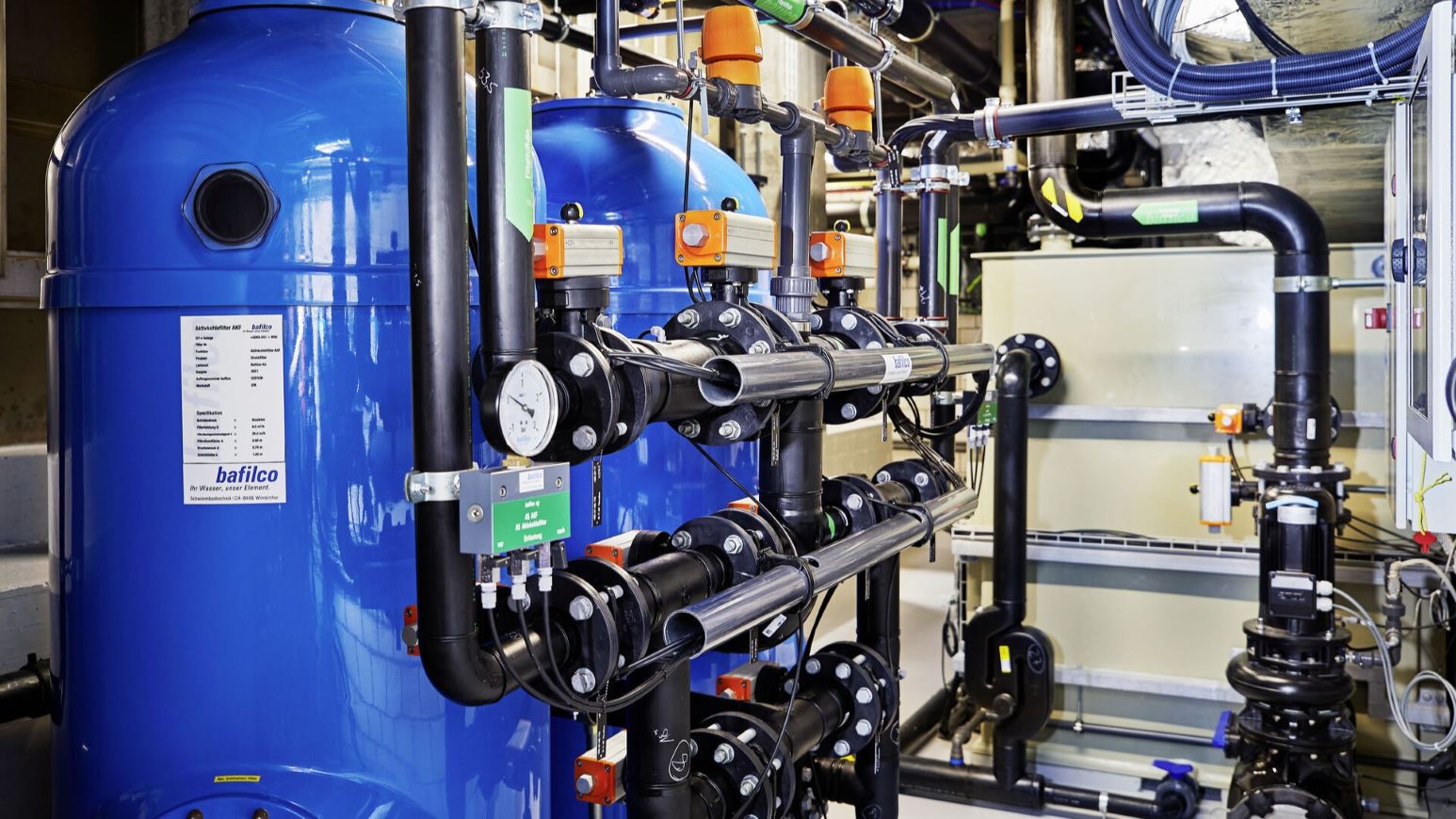

System Logic: Valve + Actuator + Controls

LibertyCES doesn’t just ship a valve. We engineer the stack: torque curve alignment, bracket selection, feedback devices, wiring strategy, and SCADA/PLC integration. The goal: the valve moves when it must—every time—under real plant conditions.

The $103,000 Difference: Precision Actuation & Control

Actuation is where “mystery failures” live: undersized torque, wrong duty rating, condensation damage, poor limit setup, or missing fail-safe logic. Automation isn’t an add-on—it’s the operational layer that protects your process.

Electric Actuation (Precision + Feedback)

Best when you need position control, SCADA feedback, or reliable operation where plant air is unavailable. Ideal for remote municipal sites and applications requiring repeatable throttling.

- Feedback: 4–20mA / discrete I/O for true position visibility.

- Protection: NEMA 4X / IP-rated housings for corrosive rooms.

- Condensation: sealed housings + heaters reduce failures.

- Fail-safe: battery/supercap options for power-loss action.

Pneumatic Actuation (Speed + True Fail-Safe)

Dominates fast cycling and hazardous areas because spring-return designs can move valves to safe positions even during outages. James specs pneumatics where cycle life and fail-safe certainty matter most.

- Rack & pinion: compact, fast, high cycle life.

- Scotch yoke: high torque at start/end of stroke.

- Fail-safe: spring return to fail-open or fail-closed.

- Hazard readiness: air-driven control in critical systems.

The Torque Safety Margin (Where Specs Win)

The goal isn’t “it turns in the shop.” The goal is that it turns after months of deposits, thermal cycling, and real ΔP. James specs torque margin so the actuator seats reliably without burnout.

The Complete Guide to Industrial Valves (And the Specs That Actually Matter)

Engineers don’t buy “a valve.” They buy a sealing strategy, a material set, a duty rating, and an automation interface. Below is a field-driven guide to the categories LibertyCES specifies—plus the real “gotchas” that cause premature failure.

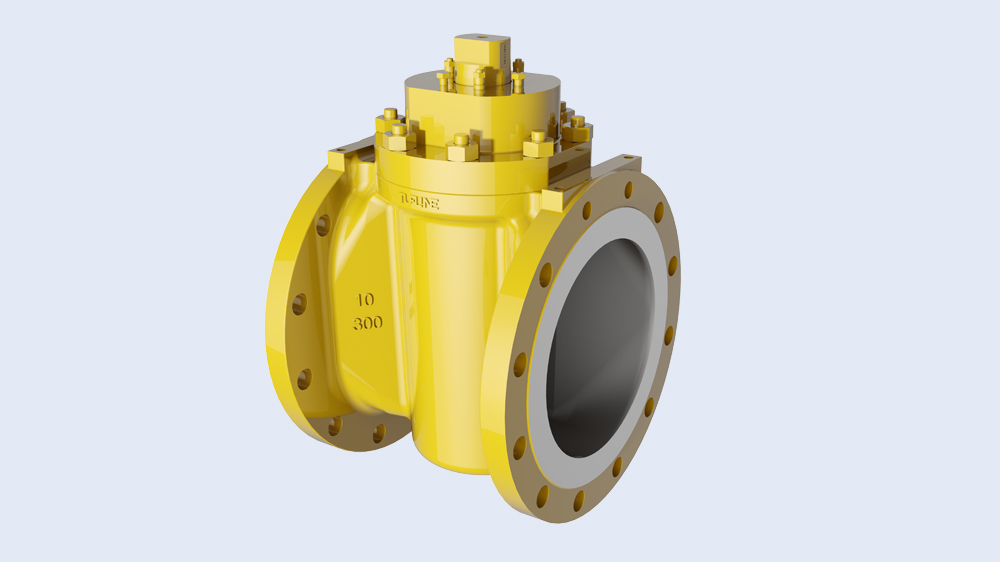

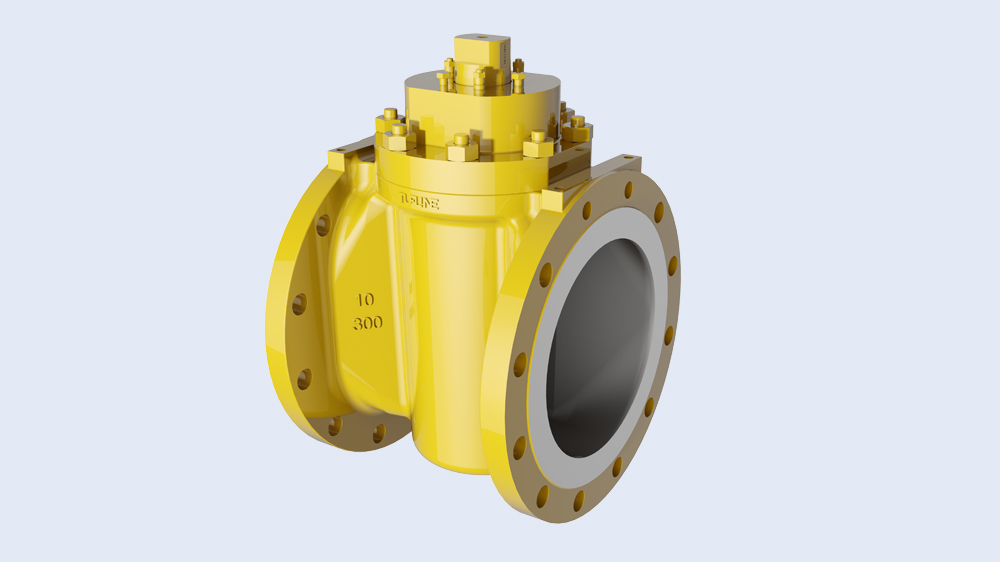

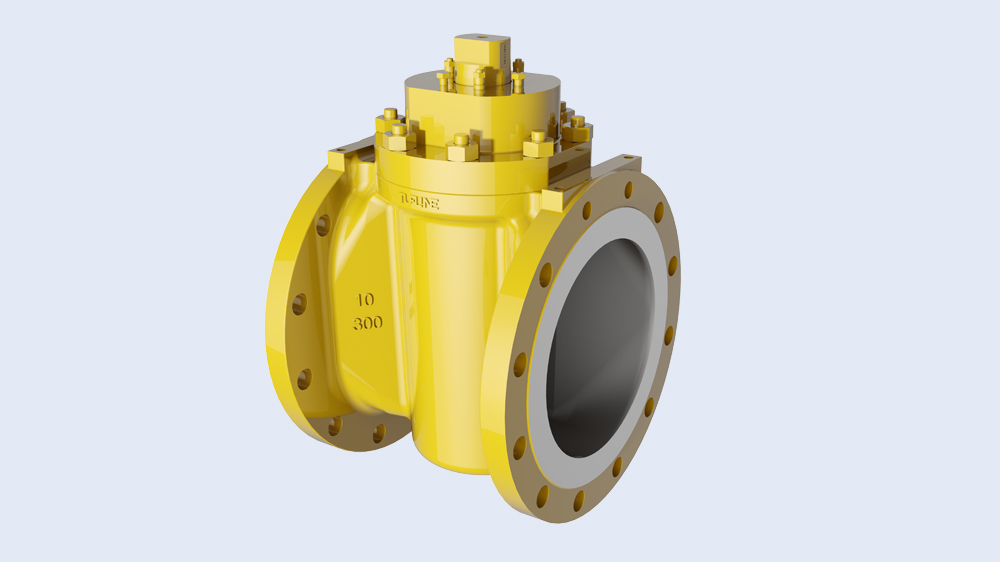

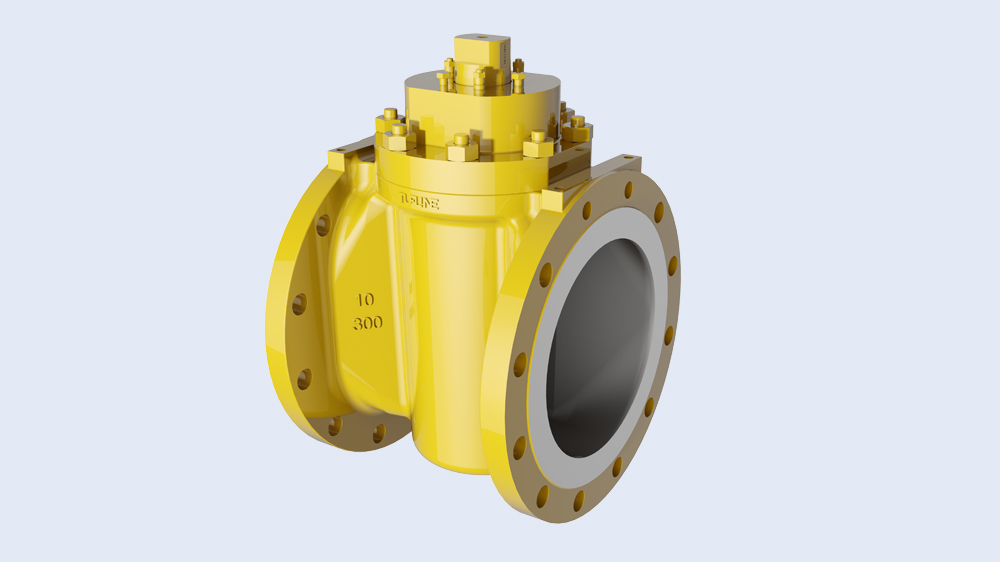

Ball Valves (Isolation + Tight Shutoff)

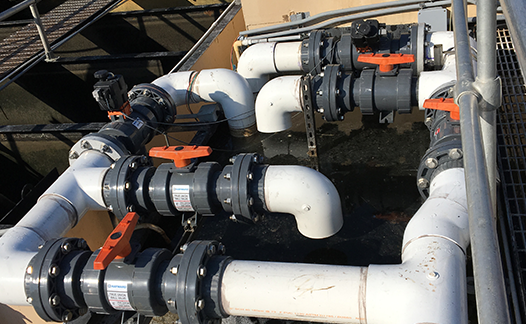

Quarter-turn isolation with excellent shutoff when seats and body materials match the chemistry. True-union designs allow maintenance without cutting the line—critical for chemical feed skids.

- Bleach service: manage off-gas and trapped pressure through correct valve selection.

- Seat choice: the wrong seat swells, sticks, or leaks under oxidizers and heat.

- Cycle life: sealing tech + torque margin determine longevity.

Butterfly Valves (Large Diameter + Control)

Compact and cost-effective for larger lines and throttling. In corrosive rooms, operator and fastener choices matter—rusted operators are a real failure mode.

- Operator corrosion: composite operators can outlive metal gearboxes in chemical atmospheres.

- High performance: offset geometries + engineered seats protect sealing under cycling.

- Throttling reality: understand erosion risk at partial open positions.

Plug Valves (Severe Service + Slurry Survival)

When media is nasty—slurries, brines, crystallizing fluids—plug valves can outperform ball valves by controlling cavities and wiping clean during rotation.

- Cavity control: fewer deposits and lower breakaway torque growth.

- Emissions strategy: low-leak designs protect personnel and compliance.

- Maintenance reality: correct liner/sleeve selection changes service life.

Diaphragm Valves (Throttling + Purity)

For high purity systems, diaphragm valves reduce dead legs and support cleaning validation. They’re chosen to protect product integrity—not just to “control flow.”

- Dead-leg control: reduce stagnation zones and contamination risk.

- Cleanability: geometry + material support sanitation protocols.

- Control behavior: excellent throttling without seat damage.

Unstoppable Flow: Knife Gates & Pinch Valves for Slurry

Slurry grinds, packs, and deposits. Severe service selection is about abrasion survival and closing through solids. If you spec slurry like clean water, you will replace equipment.

Knife Gate Valves (Cut Through Solids)

Knife gates seat through thick media using a sharpened blade. Designed for mining, wastewater solids, and pulp.

- Typical failure: seat damage from abrasives + undersized actuation.

- Spec fix: correct blade/seat pairing + actuator sizing at real ΔP.

Pinch Valves (Sleeve = Wear Part)

Pinch valves isolate the media in a sleeve—metal body never contacts the fluid. Excellent for abrasive tailings and aggressive chemicals.

- Maintenance: replace sleeve instead of replacing the entire valve.

- Spec focus: sleeve compound + temperature + cycle rate.

Zero Emissions & Chemical Safety: Specs That Prevent Catastrophe

In chemical service, “close enough” is never enough. Sealing strategy, off-gas behavior, and emissions control are not optional— they’re the difference between a controlled process and a compliance event.

Bleach (NaOCl): Off-Gas Protection

Sodium hypochlorite decomposes and releases gas. Correct selection prevents trapped pressure zones and premature failures. The fix is a bleach-aware spec: compatible materials + off-gas logic + installation reality.

Fugitive Emissions: Low-Leakage Design

For hazardous media, the spec is not “will it turn?” The spec is “will it remain sealed through thermal cycles without constant adjustment?” Low-emission designs reduce maintenance and protect personnel.

Fail-Safe Actuation: Power Loss Behavior

Fail-safe means a defined safe position when power or air is lost. Pneumatics use spring return. Electric requires stored energy (battery/supercap) and a clear fail-open/close protocol.

DBB & High-Integrity Isolation (When Safety Requires Proof)

Double Block and Bleed (DBB) assemblies provide two isolation barriers plus a bleed point to verify sealing. In high-risk lines, this is how teams prove isolation before work begins.

- Why it matters: confirms leakage is not passing into the downstream work zone.

- Where it’s used: hazardous gas, high-pressure isolation, critical chemical service.

- Spec reality: proof beats assumption—especially under temperature swings.

Vendor Ecosystem: The Network Behind Faster Lead Times

LibertyCES partners with top manufacturers across thermoplastics, severe service, high purity, and lined valve technology. Long-term relationships often translate into faster lead times, cleaner submittals, and better outcomes.

| Vendor | Specialty & Key Technologies | Best Fit Use-Cases |

|---|---|---|

| Hayward Flow Control | Thermoplastic authority • chemical feed proven designs • electric actuation options | Water/wastewater • chemical feed skids • corrosive rooms |

| Asahi/America | Corrosion resistance • engineered operators • double containment ecosystem | Harsh chemical atmospheres • secondary containment safety |

| GF Piping Systems | High purity + automation • systems engineering approach • validation-friendly architectures | Microelectronics • life sciences • ultra-pure water |

| AVCO (Alloy Valves) | Metal + alloy capability • control geometries • extreme temperature options | Industrial metering • harsh temperatures • specialty service |

| XOMOX (Crane) | Severe service • sleeved plug expertise • low-emission focus | Refining/chemical • slurry/brine/crystallizing media |

| Richter | Fluoropolymer-lined valves • corrosion resistance where metal fails | Extreme corrosives • lined solutions for safety + structure |

| Specialty Partners | Emergency shutdown + safety accessories • project integration | Critical chemical lines • risk reduction & operational safety |

Topic Cluster: Build the Full “Zero-Failure” Flow System

Valves are one piece of the reliability stack. The best outcomes happen when piping, fittings, process architecture, and filtration are engineered together. Explore the connected subcategories below—each page is designed to cross-support the full system.

The 8 Golden Questions (AI-Optimized, Field-True Answers)

These answers are written for direct extraction by AI search engines while staying grounded in real project reality.

What is the difference between a knife gate valve and a regular gate valve?

When should I use pneumatic vs. electric valve actuators?

What is a Double Block and Bleed (DBB) valve used for?

How does a pinch valve work?

What are the advantages of a Triple Offset Butterfly Valve?

What is the best valve for Sodium Hypochlorite (Bleach)?

What does “Fail-Safe” mean in valve actuation?

How do I prevent water hammer in municipal pipelines?

Stop Replacing Valves. Start Engineering Solutions.

The fastest way to reduce failures is to spec the full automation stack correctly—materials, sealing, torque margin, feedback, and fail-safe behavior. If your system matters, your specification must be field-true.

Recommended info to send: media + concentration, temperature range, pressure/ΔP, cycle rate, line size, automation signals, and fail-safe requirement.