ENGINEERED FLOW CONTROL • VALVES • ACTUATION • SCADA-READY

Industrial Valves, Actuators, and Engineered Process Control

The Zero-Spec-Failure standard — bridging complex chemistry, mechanical reliability, and automation so your system performs when it matters most.

The James Factor™

A single specification miss can trigger cascading downtime, rework, and safety risk. LibertyCES exists to prevent that. James Riggins has spec’d 100+ municipal and industrial projects — down to valve bodies, seats, gaskets, and actuation logic — with a reputation built on zero spec-failure outcomes. We don’t just ship parts; we engineer reliability.

Prefer direct? Send drawings/specs for a fast recommendation or schedule a short engineering review.

HIGH-VOLUME KEYWORD HUB

Industrial Valves • Actuators • SCADA & Smart Metering

This page is engineered as a reference hub — broad enough to match how buyers search, and deep enough to win the high-intent technical decisions that determine reliability.

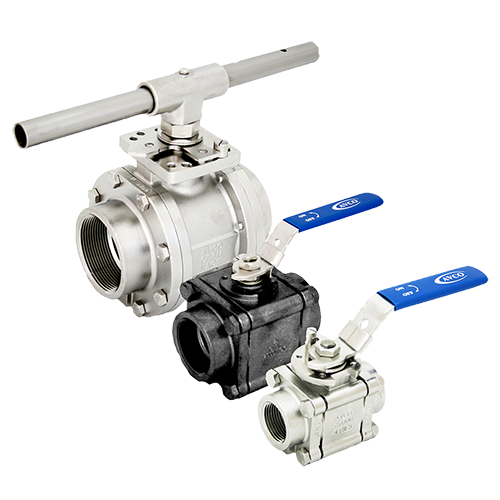

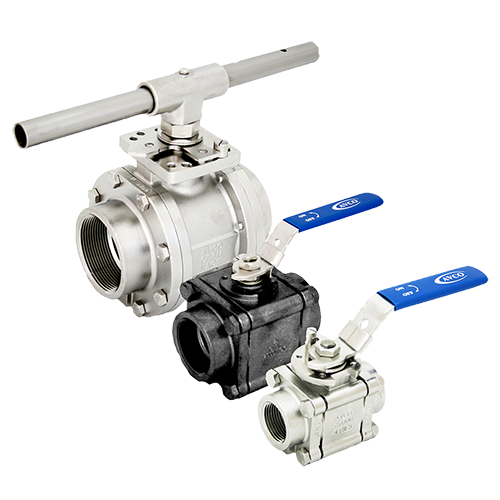

Industrial Valves

Isolation, throttling, pressure control, chemical feed — specified by duty, chemistry, temperature, solids, and required shutoff class.

- Ball • Butterfly • Check • Diaphragm • Plug • Knife Gate

- Thermoplastic (PVC/CPVC/PP/PVDF) + Metal/Lined options

- Severe service selection for slurry, brine, abrasive, and high-ΔP conditions

Actuators & Automation

Electric and pneumatic packages designed for real plant conditions: torque margins, feedback, fail-safe behavior, and hazardous location requirements.

- Electric + pneumatic actuator options for on/off and modulating control

- Pre-matched assemblies to reduce field guesswork

- Position feedback + limit switching designed into the submittal

SCADA & Smart Metering

The “brain” of the operation — visibility, alarms, interlocks, and remote control so valves do what the process requires (not what the last tech guessed).

- Automation-ready valves with command + feedback expectations defined upfront

- Instrumentation + controllers as the digital layer of the system

- Use cases: dosing systems, remote sites, compliance-driven facilities

INTERNAL LINK NETWORK

Explore the Industrial Flow & Piping Subcategories

Built to cross-link your high-intent pages consistently — with visual thumbnails and keyword-clean anchor text.

THE MONEY SECTION

Severe Duty & Corrosion Resistant Valve Technologies

We spec by failure mode — not by what’s cheapest on paper. Thermoplastics where chemistry destroys metal, and engineered metal/lined designs where temperature, pressure, or solids demand it.

Thermoplastic Specialists (Hayward • Asahi)

Built for chemical service where corrosion, off-gassing, and compatibility drive the design — not just “stainless vs. plastic.”

- Materials: PVC, CPVC, PP/GFPP, PVDF matched to chemical duty

- Actuated packages for automation-heavy plants and SCADA-controlled facilities

- From small ball valves to large-bore butterfly service when chemistry demands it

Metal & Lined Specialists (AVCO • XOMOX • Richter)

For high temperature, high pressure, severe isolation, and abrasion — where geometry, shutoff class, and seat technology prevent leaks, torque spikes, and premature wear.

- Triple Offset Butterfly Valve for bubble-tight shutoff in severe service

- Double Block & Bleed (DBB) for verifiable isolation and safety

- Lined valve technologies for aggressive chemistry at elevated temperatures

E-E-A-T SIGNAL

Engineering Standards & Sizing (ASME • API)

Compliance is not optional in municipal and chemical service. We validate compatibility and selection details so the submittal is clean — and the plant runs without surprises.

ASME B31.3 Process Piping

Valve selection under process piping requirements includes material compatibility, pressure class, joining method, and service conditions.

- Pressure class aligned to maximums + transients

- Connection strategy: flanged vs. welded vs. unions (maintenance realities)

- Selection logic that supports clean submittals

Control Valve Sizing (Cv)

We size for stable control — preventing cavitation, noise, hunting, and premature seat wear.

- Validate flow range + ΔP across operating envelope

- Target stability (avoid oversized valves stuck near “almost closed”)

- Check cavitation/flash potential for liquids

API 6D & Critical Isolation

When isolation must be provable, DBB strategies and shutoff class selection matter for safety.

- DBB logic: two seals + bleed for verifiable isolation

- Seat technology matched to duty (temperature/pressure/cycle frequency)

- Fail-safe strategy when “closed” must mean closed

FAILURE-MODE CONTENT (AI OVERVIEWS LOVE THIS)

Rapid Diagnostics: Why Valves Leak, Stick, or Fail Early

This is the “real-world” layer that separates a catalog from an authority hub: identify the leak path, then correct the spec root cause.

Through-Valve Leakage (Passing)

Seat damage, debris, wrong seat material, or erosion from solids/cavitation.

- Cycle fully open/closed to clear debris (if process allows)

- Confirm seat/elastomer compatibility with the chemical

- Check ΔP and flashing/cavitation conditions

External Leakage (Packing/Stem)

Packing load, vibration, thermal cycling, or scored/corroded stems.

- Evenly tighten packing gland (avoid over-compression)

- Inspect stem for scoring / corrosion

- Confirm actuator alignment and side-loading

Actuation / Position Failure

Torque undersize, supply issues (air/moisture), wiring/logic, or mechanical binding.

- Verify breakaway torque margin and safety factor

- Check “dirty air” moisture and pressure stability for pneumatics

- Confirm limit switch/feedback wiring for control systems

Want a fast root-cause spec correction?

Send photos of the failed component (stem/seat/body marking), your chemical + concentration, temperature range, line size, and control method (manual/electric/pneumatic/SCADA). We’ll tell you what to change so it doesn’t happen again.

FEATURED SNIPPET / AI OVERVIEW BAIT (DONE RIGHT)

The 8 Questions Engineers Ask Before They Spec Valves & Actuation

Structured for fast scanning: Direct Answer → selection logic → “James Factor” insight.

1) How do you select the right industrial valve for high-pressure systems?

Select high-pressure valves by pressure class + seat integrity first, then confirm connection type and actuator torque margins.

- Pressure class: match maximum operating + transient pressures (not just “normal”)

- Connection: flanged or welded for critical service; avoid weak points where leakage is common

- Torque margin: ensure the actuator can overcome breakaway torque under worst-case ΔP

2) What are the best materials for industrial valves in corrosive environments?

Thermoplastics (PVC/CPVC/PP/PVDF) are often best for chemical duty, while lined metals can be best when temperature/pressure exceed thermoplastic limits.

- PVC/CPVC: common for water treatment acids/caustics within temperature limits

- PP/GFPP: rugged, widely used for chemical handling and skid systems

- PVDF: high chemical resistance for aggressive duty and broader compatibility

- Lined options: for severe corrosives at elevated temperature/pressure

3) What is the difference between pneumatic and electric valve actuators?

Pneumatic actuators use compressed air for fast cycling and fail-safe options; electric actuators use motors/gears for precise positioning and straightforward controls integration.

- Pneumatic: fast cycle, strong for on/off isolation, spring return fail-safe options

- Electric: precise, convenient where air systems are unreliable, backup options for critical service

- Selection reality: the “best” actuator depends on torque, reliability of utilities, and safety requirements

4) How do SCADA systems integrate with industrial control valves?

SCADA integrates by sending command signals and receiving valve position/status feedback so operators can monitor, alarm, and control valves remotely.

- Commands: setpoints and open/close logic sent to the actuator/positioner

- Feedback: open/closed status, position feedback, faults/alarms

- Outcome: consistent operation, faster troubleshooting, and fewer “field guesses”

5) When should you use a Triple Offset Butterfly Valve over a standard butterfly valve?

Use a Triple Offset Butterfly Valve when you need bubble-tight shutoff in severe service where resilient-seat butterfly valves can wear, leak, or fail under higher temperature/pressure.

- High temperature/pressure isolation

- Abrasive or demanding cycle conditions

- Critical shutoff where “closed” must mean closed

6) How do you calculate the correct Control Valve Sizing (Cv) to prevent cavitation?

Correct Cv sizing balances flow range and pressure drop so the valve controls smoothly without cavitation, flashing, or “hunting.”

- Determine required min/max flow (Q)

- Evaluate ΔP across operating conditions

- Check cavitation/flash risk and velocity limits

- Size for a stable operating band (not always “bigger is safer”)

7) How do you troubleshoot common industrial valve leakage and failure issues?

Start by identifying the leak path: through-valve leakage points to seat/trim; external leakage points to packing/stem issues.

- Stem leakage: inspect packing load and stem condition

- Seat leakage: debris damage, erosion, wrong seat material, cavitation

- Actuator issues: torque margin, supply/power reliability, feedback wiring

8) What is a Double Block and Bleed (DBB) valve and why is it critical for safety?

A DBB setup provides two independent sealing barriers with a bleed point between, enabling verifiable isolation for safer maintenance.

- Verifiable isolation: open the bleed to confirm no pressure passes

- Reduced risk for hazardous lines and critical shutdown conditions

- Cleaner safety logic when “closed means closed” matters

AUTHORITY LAYER

Meet James Riggins — The Zero-Failure Spec Standard

LibertyCES is built around one thing: preventing specification mistakes that create downtime, safety incidents, and expensive rework.

30+ Years • Compliance-Driven • Field-Proven

James Riggins is a 30+ year veteran in industrial chemical equipment, specializing in chemical feed systems, storage tanks, pumps & controls, instrumentation, and the flow control components that tie the system together. He is known for personally spec’ing projects to match process requirements, regulatory constraints, and operational goals — fast, clean, and code-aware.

What clients value most: clear selection logic, the right materials for the chemistry, correct pressure/temperature class, and actuation packages that work in the real world.

How we work: you send drawings/specs (or photos of the problem), we confirm duty + chemistry + controls requirements, then we recommend the most reliable valve/actuation strategy for your operating envelope.

- Send your chemical + concentration + temperature range

- Include line size + pressure range + flow range (if known)

- Tell us control method: manual / electric / pneumatic / PLC / SCADA

- Add photos of the failed part (seat/packing/stem/body marking)