GORE™ Expanded PTFE Gaskets & Form-in-Place Sealants | Zero-Leak Certification

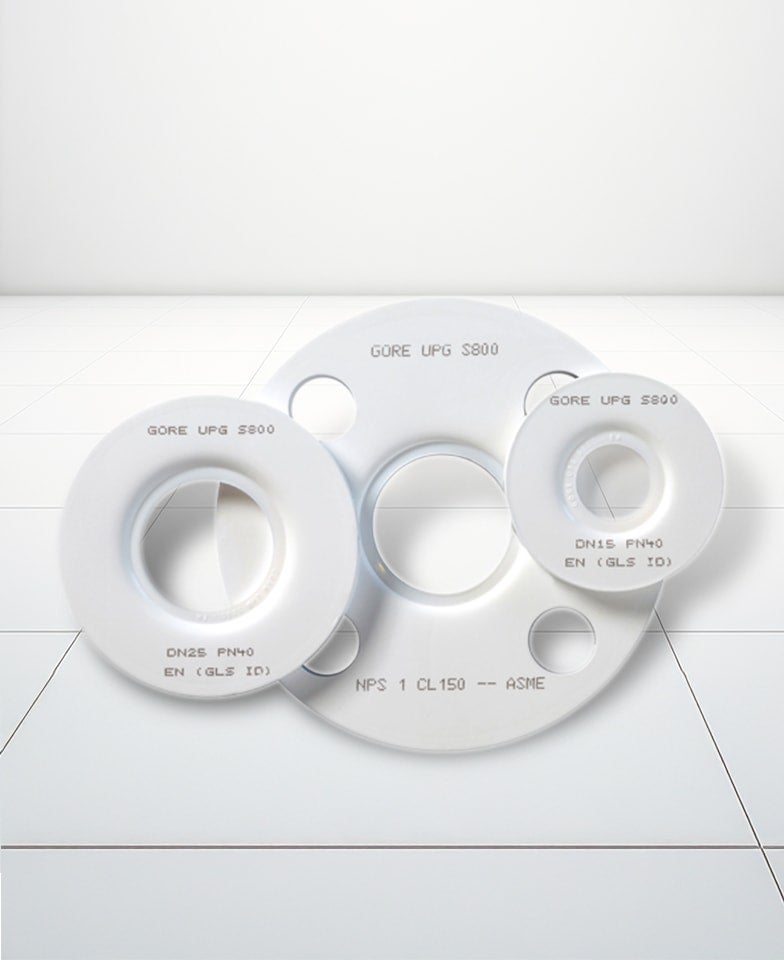

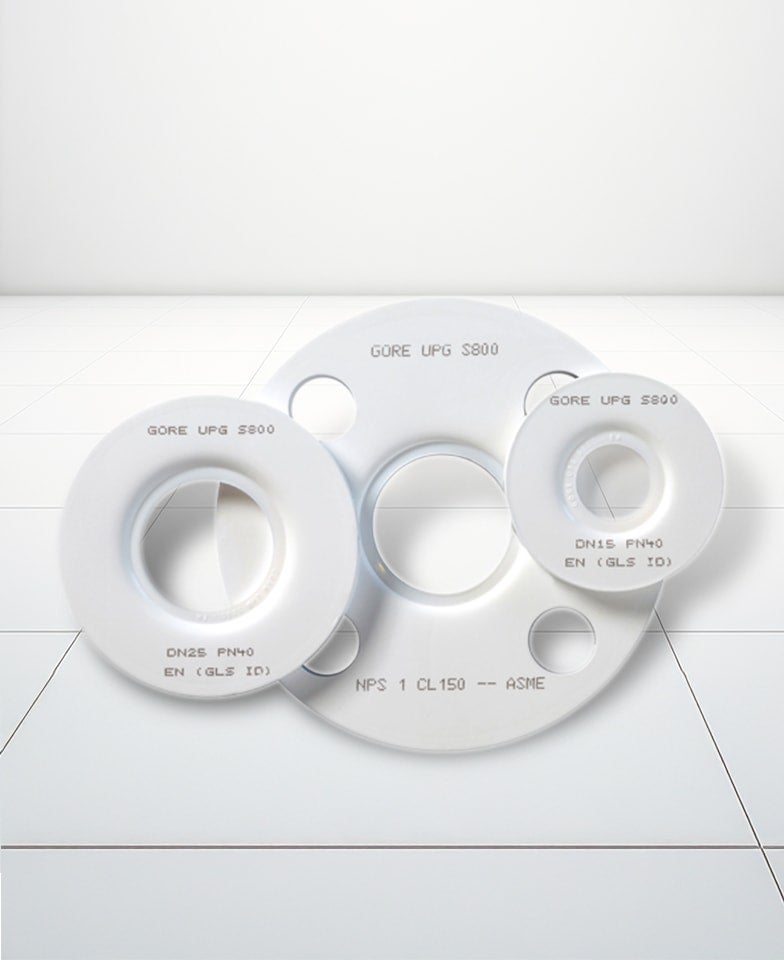

One Gasket. Zero Leaks. Total Inventory Consolidation.

Replace 3+ gasket types with the GORE™ Universal Pipe Gasket (Style 800). The only 100% ePTFE solution for Steel, Glass-Lined, and FRP flanges.

“Stop buying rubber for acids. Stop buying standard PTFE that creeps. We specify GORE ePTFE to eliminate the #1 cause of chemical leaks: Cold Flow.”

Why Expanded PTFE (ePTFE) Beats Standard Teflon

Standard PTFE is dense and prone to relaxation under load. That “cold flow” reduces bolt stress over time and turns a tight flange into a seep path. Expanded PTFE is engineered differently: a multi-directional microstructure designed to resist creep so the seal stays stable.

Custom Shapes, Heat Exchangers, Irregular Equipment

When you’re sealing non-standard equipment faces or large patterns, sheet gasketing enables custom fabrication while maintaining the benefits of ePTFE.

The 2-Minute Emergency Repair: Form-in-Place Gasketing

Think of it as a universal gasket on a spool. GORE™ Joint Sealant compresses to fill pits, scratches, and flange irregularities where rigid gaskets struggle.

Perfect For

Large diameter flanges, tank manways, shutdown repairs, and worn/pitted faces where you need a reliable seal without custom cutting.

Protect Your Glass-Lined Assets

Glass-lined and FRP equipment is expensive and unforgiving. The wrong gasket style can require excessive bolt load and create cracking risk. Specialized gasket tape designs help seal at lower load to protect the flange while maintaining a tight chemical seal.

Low-Bolt-Load Sealing for High-Value Equipment

Ask for guidance on tape selection and installation method for glass-lined steel, FRP, and mixed-material connections.

Partnered with Allied Fluid Products — West Coast GORE supplier support for industrial sealing programs.

Consolidate Gasket Inventory. Reduce Leak Risk.

Send your current gasket inventory list and flange materials. We’ll identify mismatch risks (like rubber on acid lines), recommend consolidation pathways, and help standardize sealing across steel, glass-lined, and FRP equipment.

Definitive Answers

Clear definitions used by engineers and maintenance teams to prevent repeat leaks.

What is the difference between PTFE and Expanded PTFE?

Standard PTFE is dense and prone to "cold flow" (thinning under pressure), leading to bolt loosening. Expanded PTFE (ePTFE), found in GORE gaskets, is chemically processed to have a microporous structure that resists creep, maintaining bolt load and seal integrity indefinitely.

What is a Form-in-Place Gasket?

A form-in-place gasket is a pliable sealant, such as GORE™ Joint Sealant, that is applied as a continuous cord directly onto a flange surface. It compresses to fill irregularities and creates a custom-fit seal without requiring pre-cutting or precise measurements.

What is the temperature rating of GORE Gaskets?

GORE™ Industrial ePTFE gaskets are rated for use from -450°F to +600°F (-268°C to +315°C), making them suitable for cryogenic systems and high-temperature chemical processes alike.