Industrial Chemical Transfer Hoses (Acid • Suction • Discharge) | Custom Assemblies

Stop Guessing Compatibility. Engineer the Transfer.

From 98% Sulfuric Acid to Food-Grade CIP: We match the liner to the liquid to prevent silent failures.

“A hose isn't just a tube; it's the most vulnerable part of your process. We don't sell 'general' hoses. We match the liner—UHMWPE for aggressive solvents, EPDM for mild acids—to ensure your operators are safe and your system is compliant.”

Choose the Hose by Severity Level

Three proven paths: versatile transfer, sanitary high-purity, and heavy-duty bulk offloading.

CHEM ONE™

General Chemical Transfer

NOVAFLEX 4200

Food & Pharma (CIP/SIP)

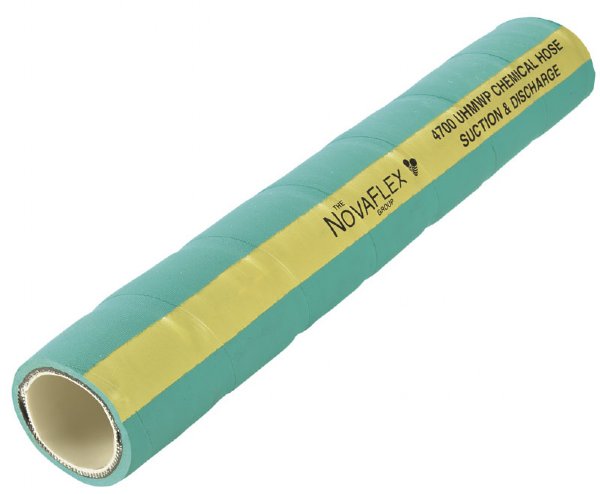

NOVAFLEX 4700

Heavy Duty Suction/Discharge

Crimped Ends, Flanges, Camlocks, and Safety Hardware

We build assemblies for suction and discharge service and match end connections to your system requirements. Share your chemical, temperature, pressure, and connection type to prevent mis-spec and premature liner failure.

Built for Acids, Solvents, and Industrial Offloading

Selecting the wrong liner often fails silently first — swelling, softening, embrittlement, and delamination. We spec the liner to the liquid and the reinforcement to the duty cycle.

Mini Compatibility Guide

- Sulfuric Acid (H2SO4): Recommend Novaflex 4700 (UHMWPE).

- Hydrochloric Acid (HCl): Recommend Composite or UHMWPE.

- Sodium Hypochlorite (Bleach): Recommend specialized XLPE.

The Pump Connection

Don't connect a weak hose to a strong pump. We spec hoses to match the flow rate and pressure of your Chemical Transfer Pumps (AODD, Centrifugal) to eliminate cavitation and hose collapse.

Direct Answers

Clear definitions that prevent suction collapse, liner failure, and chemical mismatch.

What is the best hose material for sulfuric acid?

For concentrated sulfuric acid (up to 98%), an Ultra-High Molecular Weight Polyethylene (UHMWPE) liner, found in our Novaflex 4700 series, is the industry standard. It offers superior chemical inertness compared to standard rubber (EPDM) and prevents the liner from swelling or degrading under acid exposure.

What is the difference between chemical suction and discharge hose?

A chemical suction hose is reinforced with a wire helix (metal or plastic) to prevent the hose from collapsing under vacuum pressure (negative pressure) when drawing fluid from a tank. A discharge hose is typically soft-walled and designed only to push fluid out under positive pressure. Using a discharge hose for suction will result in immediate hose failure.

Is UHMWPE better than XLPE for chemical hoses?

Both are excellent, but UHMWPE (Ultra-High Molecular Weight Polyethylene) generally offers a broader range of chemical resistance (98% of chemicals) and is often preferred for aggressive solvents and corrosives. XLPE (Cross-Linked Polyethylene) is a durable, cost-effective alternative for many industrial acids but is less flexible than UHMWPE.

Check My Chemical Compatibility

Not sure if your current hoses are safe? Send James Riggins your chemical MSDS and operating temperature. We will confirm liner compatibility and spec the correct camlock/flange assembly for your system.