Industrial Wastewater Treatment & Chemical Transfer Systems in California

Water Treatment Systems • Chemical Transfer Solutions • Water Purification Systems

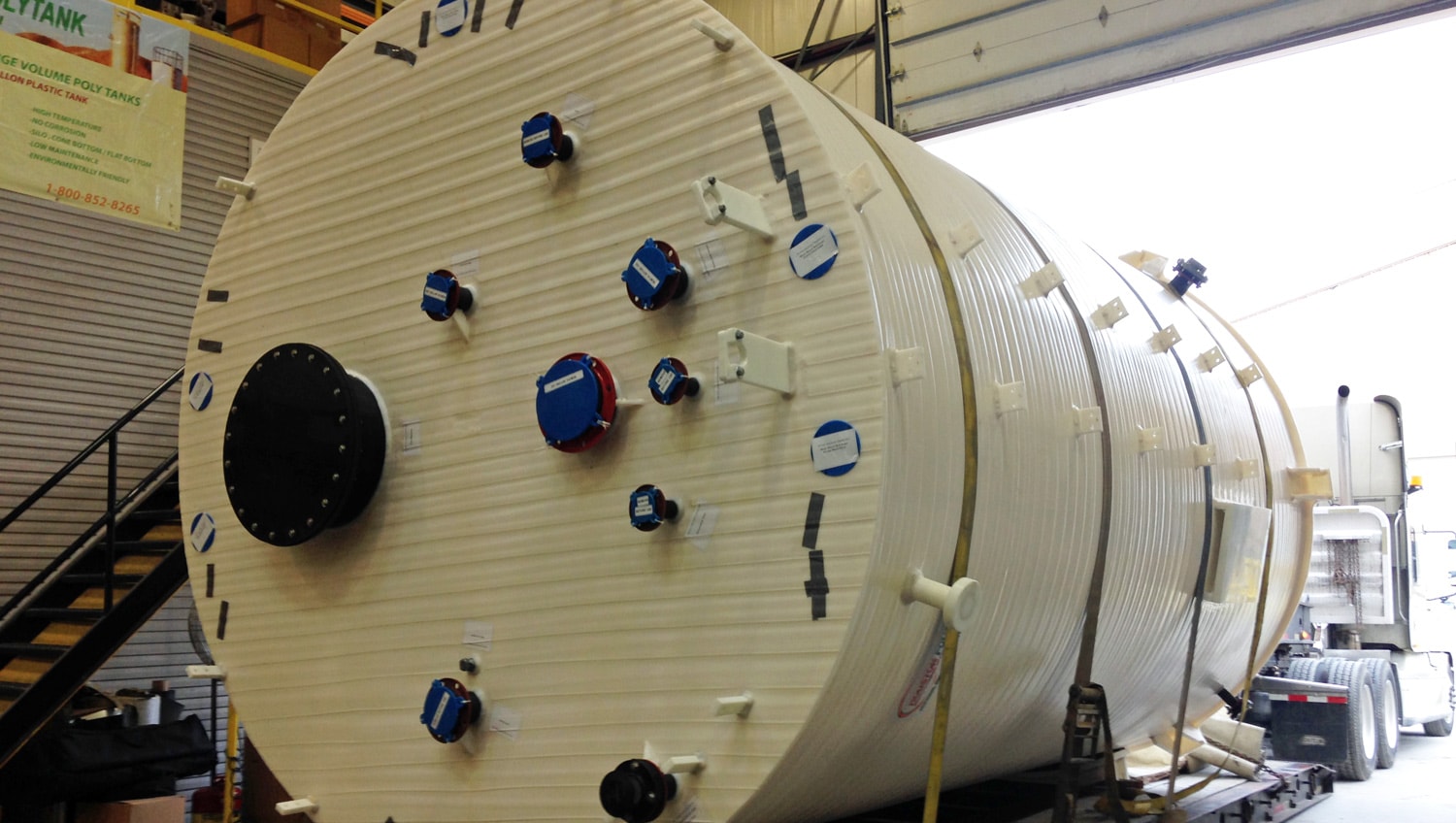

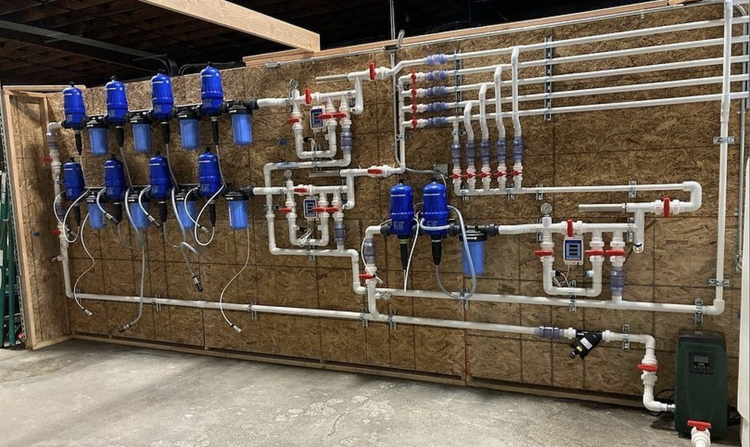

LibertyCES helps municipal plants, agriculture, and industrial facilities spec water treatment and industrial wastewater treatment solutions — pumps & controls, storage tanks, instrumentation, accessories, fittings, and water treatment chemicals — matched to your chemistry, temperature, and duty cycle. Every project is personally spec’d by James Riggins for code-compliant, long-life performance.

Support for industrial wastewater treatment systems and chemical transfer solutions; specification of pumps and controls, storage tanks, instrumentation, accessories, fittings, and water treatment chemicals; municipal and industrial water treatment in California.

Diaphragm Pumps for Slurry Transfer: 100 GPM with Zero Failures

A mining client faced catastrophic seal failures until we replaced their setup with a diaphragm pump designed for chemical transfer. Integrated with PLC and SCADA controls, the system maintained 100 GPM flow with zero seal failures — cutting downtime and boosting reliability.

Built for Uptime, Compliance & Chemical Precision

Hardware stacks that outlast corrosive duty, stabilize process variables, and protect revenue when every hour of uptime matters.

Metrics based on aggregated project outcomes and industry benchmarks. Your results will vary by chemistry, flow, and duty cycle.