Chemical & Water Storage Tanks Specced For Your Needs

Chemical Water Storage Tanks

Engineered for Compliance, Built for Harsh Duty, Spec’d to Your Chemistry

Get the right tank the first time—matched to your chemistry, temperature, and duty cycle. Protect uptime, avoid fines, and extend service life with high-performance thermoplastic tanks.

Compliance & Risk Avoidance: NSF/ANSI 61 and SPCC-ready specs help avoid $25,000+ fines per incident.

Cost Savings: Rectangular formats can cut freight up to 80%. Fewer changeouts = long-term savings.

Harsh-Duty Performance: Rated for aggressive chemistries (pH 0–14). Polypropylene handles up to 200°F. Extrusion-wound walls resist bulging & cracking.

Proven by Liberty: Delivered across municipal water, wastewater, ag fertigation, mining & chemical industries — with zero spec mismatches.

0

Fines Prevented per Spill Avoided

0

Longer Lifespan vs. Typical Alternatives

You Don’t Just Get a Tank. You Get James’ 30+ Years of Tank Specs. Longevity Guaranteed.

Real engineering judgment behind every spec — so your tank matches chemistry, temperature, and duty cycle the first time.

Material Mastery

Knows when to spec PolyPro (200°F) vs. HDPE (120°F) vs. FRP — preventing premature failures. One Liberty tank can outlast 2–3 competitor tanks.

Custom Fit to Your Application

Chemistry, flow, footprint, duty cycle, and temperature all accounted for — avoiding costly retrofits or tank resizing later.

Relationship, Not Just Equipment

James answers the phone, listens, and specs it right the first time — delivering peace of mind and saving engineering hours.

Choose a Tank Type

Flat Bottom Tanks

Lowest cost‑per‑gallon bulk storage.

Resin grade + wall thickness spec’d for 20+ year life — avoiding $50k early replacements.

Cone Bottom Tanks

100% drainage — no sludge or residue.

Used where required (e.g., sodium hypochlorite, sludge‑heavy wastewater) — saving cleaning costs and preventing compliance hits.

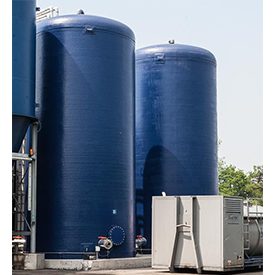

Vertical Cylindrical Tanks

Up to 50,000 gallons without bulging.

Sized for footprint + chemistry — avoiding costly retrofits or line resizing later.

Horizontal Tanks

Fits tight spaces; easy to move.

Correct supports + wall thickness prevent collapse during transport — saving loads and downtime.

Rectangular Tanks

Save up to 80% on freight.

Custom sizes fit frac tanks, containers, or trailers — avoiding building redesigns.

Polyethylene (HDPE) Tanks

95% of chemicals up to 120°F.

Correct chemical compatibility prevents attack failures and leaks.

Polypropylene (PP) Tanks

180–200°F continuous duty.

Spec’d for high‑temp processes — no melted or warped HDPE.

Fiberglass (FRP) Tanks

Outlasts steel by 20+ years.

Chosen for harsh acids/caustics — avoids corrosion failures & shutdowns.

Double‑Wall / Secondary Containment

Built‑in containment = EPA/SPCC ready.

Meets regs where required — preventing $25,000+ fines and liability.